| Name: | 0.8mm Tin Wire 63/37 with Flux Core for PCB Electronics Welding from China |

Product Description

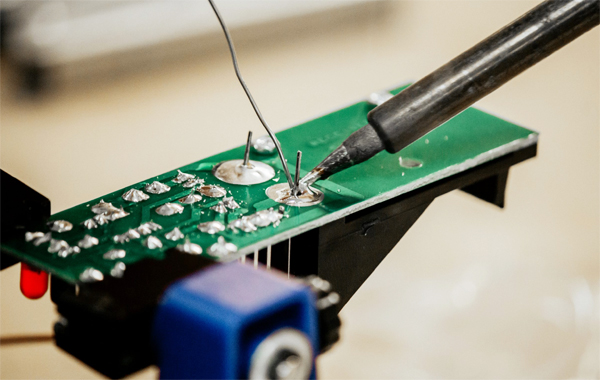

0.8mm Tin Wire 63/37 with Flux Core for PCB Electronics Welding

When it comes to PCB electronics welding, choosing the right soldering material is crucial for ensuring strong, reliable connections. One of the best options available is 0.8mm tin wire 63/37 with flux core, designed specifically for precision work in electronics. This tin wire for PCB applications offers excellent conductivity, durability, and ease of use, making it a top choice for professionals and hobbyists alike.

Why Choose 63/37 Tin Wire for Electronics?

The tin wire 63/37 composition refers to an alloy made of 63% tin and 37% lead. This ratio creates a eutectic mixture, meaning it melts and solidifies at a single temperature (183°C or 361°F), reducing the risk of cold solder joints. The 0.8mm tin wire 63/37 is particularly well-suited for PCB electronics welding because:

Precision Melting: The eutectic property ensures a smooth, even melt, perfect for delicate PCB components.

Strong Joints: The 63/37 blend provides superior mechanical strength compared to other solder alloys.

Flux Core Benefits: The tin wire with flux core eliminates the need for separate flux application, simplifying the soldering process.

Advantages of 0.8mm Tin Wire with Flux Core

The 0.8mm tin wire 63/37 is an ideal thickness for most PCB electronics welding tasks. Here’s why:

1. Optimal Thickness for Precision Work

A 0.8mm tin wire is neither too thick nor too thin, making it perfect for soldering small components like resistors, capacitors, and IC chips. It provides enough material for strong joints without excessive solder buildup.

2. Flux Core for Cleaner Soldering

The tin wire with flux core contains a rosin-based flux that cleans oxidation from metal surfaces, ensuring better adhesion. This feature is especially useful in tin wire for electronics, where cleanliness directly impacts performance.

3. Reliable Performance in PCB Assembly

Whether you're working on prototypes or mass production, the tin wire 63/37 delivers consistent results. Its low melting point minimizes heat stress on sensitive components, reducing the risk of damage.

Applications of 0.8mm Tin Wire 63/37 in Electronics

This tin wire for PCB projects is widely used in:

Consumer Electronics: Soldering connections in smartphones, laptops, and gaming consoles.

Automotive Electronics: Repairing and assembling circuit boards in vehicles.

DIY Electronics: Perfect for hobbyists building custom circuits or repairing gadgets.

How to Use 0.8mm Tin Wire for PCB Welding

To get the best results with 0.8mm tin wire 63/37 with flux core, follow these steps:

Prepare the Surface: Clean the PCB and components to remove dirt or oxidation.

Heat the Joint: Use a soldering iron (preferably temperature-controlled) set between 300-350°C.

Apply the Solder: Touch the tin wire for electronics to the joint, allowing the flux to activate and the solder to flow smoothly.

Inspect the Connection: Ensure the solder forms a shiny, concave fillet without bridges or cold joints.

Conclusion

For anyone involved in PCB electronics welding, the 0.8mm tin wire 63/37 with flux core is an excellent choice. Its precise melting behavior, strong joints, and built-in flux make it a reliable tin wire for PCB and other electronic applications. Whether you're a professional technician or a DIY enthusiast, this tin wire for electronics ensures high-quality, durable solder connections every time.

Invest in the right tin wire 63/37 today and experience smoother, more efficient soldering for all your projects!

Contact Information:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: +8613450770997