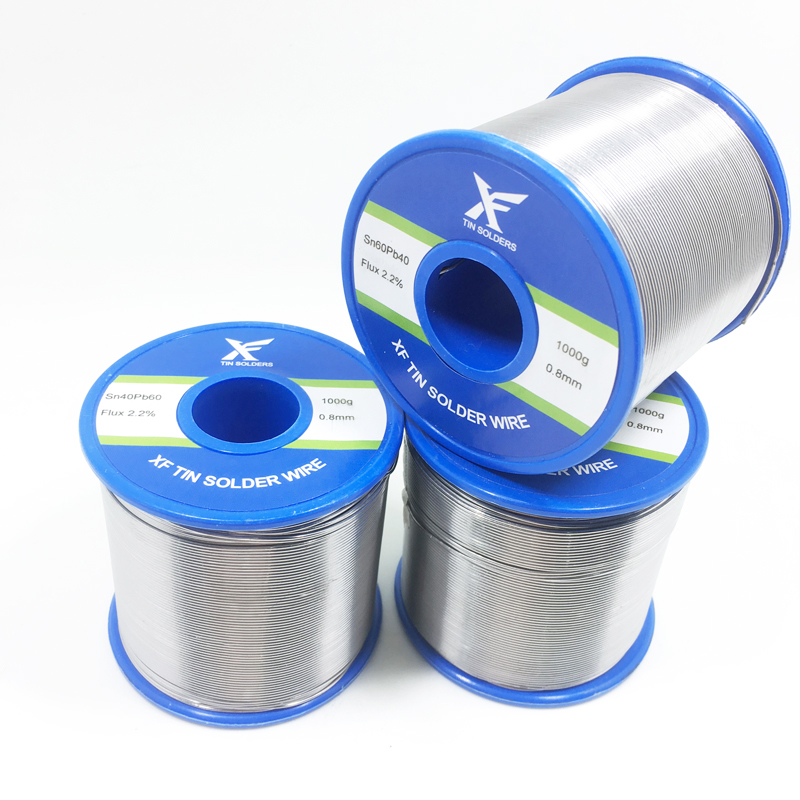

| Name: | 0.6mm, 1.6mm, 1.8mm, 2mm, 2.5mm, 3mm Soldering Lead 60/40 (Sn60/Pb40) in 250g Reel for EMS |

Product Description

High-Quality 0.6mm, 1.6mm, 1.8mm, 2mm, 2.5mm, 3mm Soldering Lead 60/40 (Sn60/Pb40) in 250g Reel for EMS

Introduction to Soldering Lead 60/40 (Sn60/Pb40)

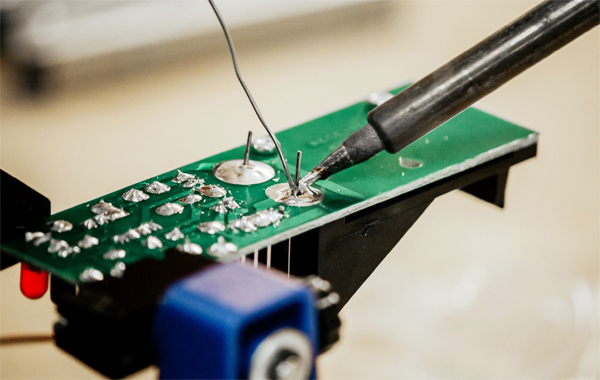

Soldering is a fundamental process in Electronic Manufacturing Services (EMS), where reliable electrical connections are crucial. One of the most trusted materials for soldering is the soldering lead 60 40, also known as Sn60/Pb40. This alloy consists of 60% tin (Sn) and 40% lead (Pb), offering excellent wetting properties, strong joints, and a manageable melting point.

For EMS providers, having the right soldering lead Sn60/Pb40 in various diameters—such as 0.6mm, 1.6mm, 1.8mm, 2mm, 2.5mm, and 3mm—ensures compatibility with different PCB components. Packaged in a convenient 250g reel, this solder wire is ideal for both manual and automated soldering processes.

Why Choose Sn60/Pb40 Soldering Lead?

The soldering lead 60 40 alloy is widely preferred in electronics manufacturing due to its:

Optimal Melting Range: Sn60/Pb40 melts at around 183°C–190°C, making it easy to work with while preventing thermal damage to sensitive components.

Excellent Flow Characteristics: Ensures smooth and even solder joints, reducing defects.

Strong Mechanical Bonds: Provides durable connections, essential for high-reliability applications.

Cost-Effectiveness: Compared to lead-free alternatives, soldering lead Sn60/Pb40 is more affordable while maintaining high performance.

Available Diameters for Different Soldering Needs

Different soldering tasks require varying wire thicknesses. Here’s a breakdown of the available soldering lead 60 40 diameters and their best applications:

1. 0.6mm Soldering Lead 60 40

Ideal for precision soldering of small SMD components.

Perfect for fine-pitch ICs and delicate circuitry.

2. 1.6mm Soldering Lead 60 40

Suitable for general PCB assembly work.

Works well with medium-sized through-hole components.

3. 1.8mm Soldering Lead 60 40

A versatile choice for both small and medium soldering tasks.

Ensures good solder flow for connectors and larger pads.

4. 2mm Soldering Lead 60 40

Best for heavier connections and thicker wires.

Used in power electronics and larger joints.

5. 2.5mm Soldering Lead 60 40

Designed for high-current applications.

Ideal for soldering large terminals and bus bars.

6. 3mm Soldering Lead 60 40

Used in industrial soldering and high-power applications.

Ensures strong, reliable joints in heavy-duty electronics.

Benefits of 250g Reel Packaging

The soldering lead 60 40 250g reel offers several advantages for EMS providers:

Convenient Handling: A 250g spool is easy to manage, reducing waste and improving efficiency.

Cost-Effective: Smaller reels minimize oxidation risks compared to bulkier options.

Compatibility: Works seamlessly with most soldering irons and automated machines.

Whether you’re using soldering lead Sn60/Pb40 250g for prototyping or mass production, this packaging ensures consistent performance.

Applications in Electronic Manufacturing Services (EMS)

EMS companies rely on high-quality soldering lead 60 40 for various applications, including:

PCB Assembly: From consumer electronics to industrial control systems.

Repair and Rework: Fixing defective solder joints efficiently.

Automotive Electronics: Ensuring durable connections in harsh environments.

Aerospace and Defense: Meeting high-reliability soldering standards.

The Sn60/Pb40 alloy’s versatility makes it indispensable in modern electronics manufacturing.

How to Store and Handle Soldering Lead 60/40

To maintain the quality of your soldering lead Sn60/Pb40, follow these best practices:

Store in a Dry Environment: Moisture can cause oxidation, reducing solder effectiveness.

Use Anti-Static Packaging: Prevents contamination in sensitive EMS applications.

Avoid Excessive Heat Exposure: High temperatures can degrade flux performance.

Conclusion: The Best Soldering Lead for EMS

For Electronic Manufacturing Services, choosing the right soldering lead 60 40 is critical for efficiency and reliability. With options ranging from 0.6mm to 3mm, and packaged in a practical 250g reel, Sn60/Pb40 solder wire ensures strong, durable connections across various applications.

Whether you need 1.6mm soldering lead 60 40 for standard PCB work or 2.5mm soldering lead 60 40 for high-power circuits, this alloy delivers consistent results. Invest in high-quality soldering lead Sn60/Pb40 250g reels to enhance your EMS production today!

By selecting the appropriate diameter and maintaining proper storage, you can optimize soldering performance and ensure long-lasting electronic assemblies.

Contact Information:

Email: xfsolder@163.com or xfsolder@gmail.com

WhatsApp/Wechat: +8613450770997