China 60 40 Sn60Pb40 Solid Core Super Wire Solder for Stained Glass

China 60 40 Sn60Pb40 Solid Core Super Wire Solder for Stained Glass

Introduction of China 60 40 Sn60Pb40 Solid Core Super Wire Solder for Stained Glass:

Composition of solder: 60 40 Sn60Pb40 (60% of tin & 40% of lead). Leaded tin alloy.

Core: solid core (solid wire) without flux. External flux must be applied before soldering.

Quality: Super Wire Solder

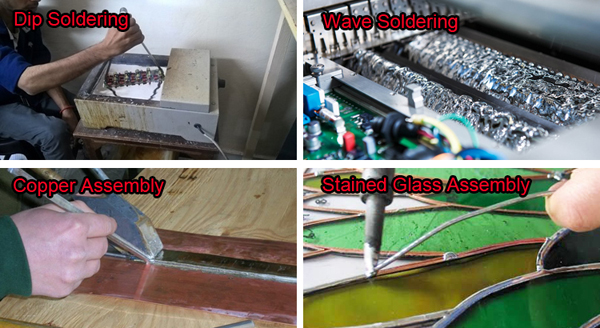

Applications: solder for stained glass

What wire diameters are available on China 60 40 Sn60Pb40 Solid Core Super Wire Solder for Stained Glass?

Production capacity wise, we can produce any wire diameter from 0.5mm to 3.2mm. To do soldering on stained glass, generally big wire diameter of solid core solder like 3mm or 3.2mm will be preferred. Because this type of solid wire solder can gives a proper amount of solder during the melting process and perfectly feel up in the gaps between the came & the glass. Alloy Sn60Pb40 60/40 solder are the perfect types of stained glass solder.

Is there any other alloys suitable for stained glass soldering besides China 60 40 Sn60Pb40 Solid Core Super Wire Solder for Stained Glass?

Optional, the composition of Sn50Pb50 solid solder or Sn40Pb60 solid core solder can be used as stained glass solder too. And these two types of solid solder contains lower tin, so their prices are a bit cheaper than the super solder 60 40. The difference is that solid core solder Sn50Pb50 or Sn40Pb60 have higher melting point & bigger pasty ranges when comparing to super solder 60 40, that means they are a bit more difficult to use when comparing to Sn60Pb40. But such a temperature difference won't be a problem for people who have rich experiene in stained glass soldering, as all these three types are common alloys to be used. We recommend green hands to use solder 60 40 to start.

If you are looking for supplier of China 60 40 Sn60Pb40 Solid Core Super Wire Solder for Stained Glass, contact us. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 008613450770997