Chinese Solder Wire Manufacturer in China

Solder Wire Manufacturer in China

This article is a lecture about how a China solder wire manufacturer produce the solder wire. Though in the market it's quite common for us to see the finished product of solder wire that already rolled into a spool, but we believe that most of the users still do not know how a roll of solder wire is made in the China solder wire manufacturing factory.

XF Solder is a factory that manufacture various types of solder wires in Foshan city of China. We are in South part of China, near Guangzhou, Shenzhen, Hongkong & Macau, thus it's very convenient to visit us, or purchase solder wires from us, because we're close to Guangzhou Port, Shenzhen Port, easy and cheap shipping.

In our factory we have both leaded solder wires and lead free solders. Today we're going to introduce about us - being as a China solder wire manufacturer, how do we produce the solder wires in China.

5 Steps of how a solder wire is produced: XF Solder - Professional China Solder Wire Manufacturer - Production process:

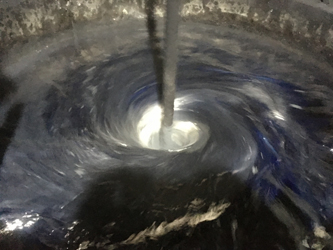

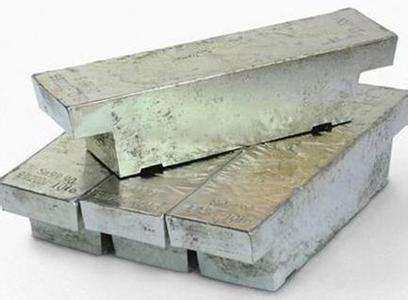

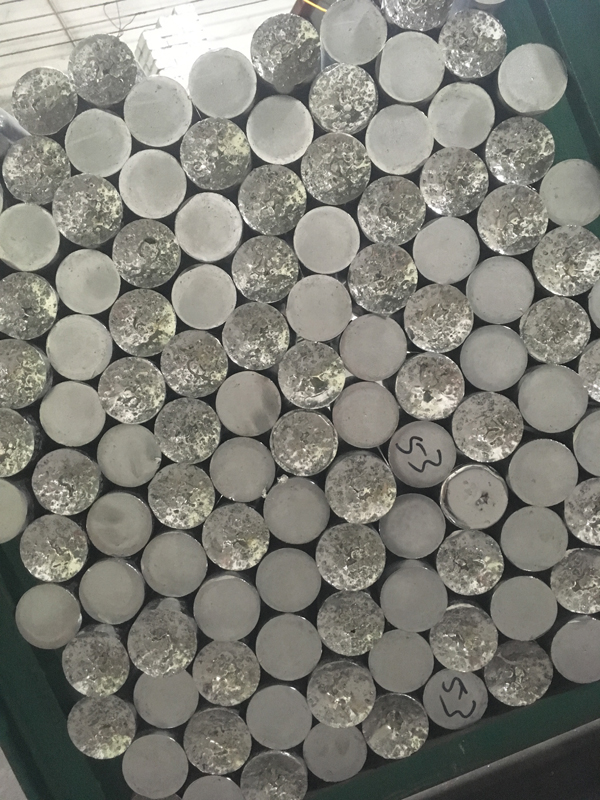

Step 1: Melting, mixing & casting of solder alloy round bars. This procedure is to melt down and mix different metals to make into alloy, if you want to produce leaded tin solder wire then you mix tin & lead ingots; if you want to produce lead free solder wire then you mix tin & copper, or tin & copper & silver ingots. When producing the tin lead alloy, make sure lead is firstly melted at 350℃ before you put tin in, add the portion of different metals properly as per the alloy you want to make. Keep stiring the melted alloy inside the melting pot and filter the melted alloy to purify it. At least, cast them into round bar form. During this process QC will do sampling to check the alloy to see if it meets the required composition.

Step 2: Extruding the round bar into big diameter wire. Make sure the round bar surface was cleaned to remove the oxidization layers. And lubricating oil is applied to the round bar surface before it's put into the extruding die, as the lubricating oil will make it easier to be extruded into wire form, this process is done under heat at a temperature of around 170℃. After this procedure, we will get a 10mm diameter hollow wire. This is a semi-finish product.

Step 3: drawing of solder wires. We being as a China solder wire manufacturer have 4 wire drawing machine. During this process, we draw the solder wires from the bigger diameter into the required wire diameter, and inject the rosin flux into the hollow core, making it a rosin flux cored solder wire.

Step 4: Wire winding. During this step, we XF China solder wire manufacturer will wind the solder wires onto plastic spools and make into the weight client ordered. Generally we have 100g/reel, 200g/reel, 250g/reel, 500g/reel, 1000g/reel solder wires.

Step 5: labeling and packing. This is the last step to turn the solder wires into the finished products. We have a circular label printed with alloy, wire diameter, weight etc and will stick it onto the reel, easy for client to classify what this solder wire is made of. And eventually small box will be used to put the solder wires, generally 20 spools or 10 spools of solder wire will be put into one box.

Additional information of Chinese Solder Wire Manufacturer in China.

The manufacturing process of solder wires in China looks quite simple, and it's already quite mature industry in China, but still how skillful the workers are, and if the factory have implemented the correct quality control procedures are crucial to the final quality of the solder wires. Hope we XF Solder - being as a professional China solder wire manufacturer, can be your Mr Right that you're looking for, if you want to buy the solder wires directly from a Chinese solder wire manufacturer from China.

We look forward to cooperating with friends worldwide.