BGA Tin Solder Paste

BGA Tin Solder Paste

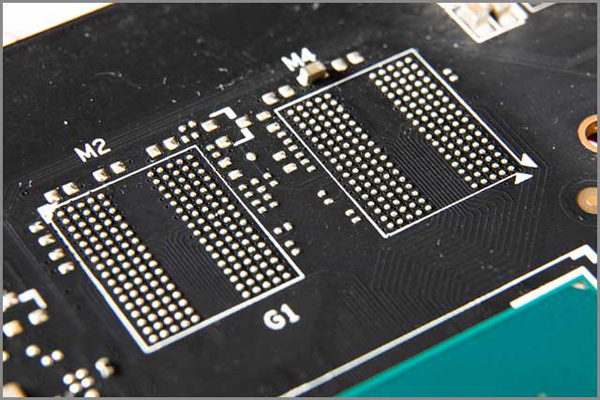

BGA (Ball Grid Array) solder paste is a

type of tin paste that is specifically designed for use in the BGA process.

This process involves attaching small balls of solder to the pads on a printed

circuit board (PCB) using a stencil and a solder paste, which is then reflowed

using heat to create the electrical connections. BGA paste is an important part

of this process, as it plays a crucial role in ensuring that the solder balls

are properly positioned and have the correct amount of solder.

Types of Tin Solder Paste:

There are several types of BGA solder paste

available on the market, each with its own unique set of features and

specifications. Some common types of tin paste include:

Lead-free tin paste: This type of BGA paste

is formulated to be free of lead, making it a more environmentally friendly and

safer option for use in electronics manufacturing. Lead-free tin solder paste

typically has a higher melting point than lead-based paste, which can make it

more challenging to work with. However, it is becoming increasingly popular due

to its environmental benefits and the growing demand for lead-free electronics.

Our lead free tin paste are ROHS compliant. Common alloys of lead tin paste we

made: Sn99Ag0.3Cu0.7 solder paste & Sn96.5Ag3.0Cu0.5 solder paste, Sn42Bi58

solder paste. And our BGA solder paste is no-clean type: it is formulated to

leave little or no residue after reflow, making it a more convenient option for

use in electronics manufacturing. No-clean tin solder paste is a good choice

for applications where a clean finish is desired, such as in the production of

consumer electronics.

Leaded tin paste, on the other hand,

contains lead as a main component. Commonly used leaded BGA solder paste are:Sn63Pb37 tin paste, Sn62Pb36Ag2 types. Leaded tin solder paste is generally

easier to work with than lead-free paste due to its lower melting point, but it

is less environmentally friendly and may not be suitable for use in certain

applications. And the cost of leaded tin paste is much more affordable than

lead free tin paste.

It would depend on your market regulation

codes and also your budget to choose the proper type of tin paste.

How to use Types of Tin Solder Paste properly?

To use BGA solder paste, it is first necessary

to prepare the PCB by cleaning and drying it to remove any contaminants that

could affect the quality of the soldering process. Next, the stencil is placed

over the PCB and the solder paste is applied to the pads using a squeegee or

other tool. The paste is then reflowed using heat to melt the solder and create

the electrical connections.

There are several factors that can affect

the performance of BGA paste, including the type and quality of the paste, the

reflow temperature, and the cleanliness of the PCB. To ensure the best possible

results, it is important to carefully select the right type of tin solder paste

for the application and to follow the manufacturer's instructions for use.

In conclusion, BGA tin solder paste is an essential

component in the BGA process, and it is important to choose the right type of

paste for the specific application. With a variety of types available, it is

possible to find a paste that meets the specific needs of any project. By

following the manufacturer's instructions and paying attention to factors such

as reflow temperature and cleanliness, it is possible to achieve high-quality,

reliable soldering results using tin paste.