Sn63Pb37 Leaded Tin Solder Bar for Wave Soldering

Sn63Pb37 Leaded Tin Solder Bar for Wave Soldering

Solder Bar is a metallic alloy that is used to

join two or more metal components together. It is melted and then allowed to

cool, forming a strong bond between the components. Solder bars are a form of

solder that are shaped into a bar or rod, making them easy to handle and use in

a variety of soldering applications. When during for electronics assembly, the

ways to use tin solder bar are by dip soldering or wave soldering.

One type of solder bar that is commonly

used in wave soldering is Sn63Pb37, which is a leaded tin solder. The

"Sn" in the name stands for tin, while the "Pb" stands for

lead. The numbers refer to the percentage of each metal present in the alloy.

In this case, the Sn63Pb37 solder contains 63% tin and 37% lead.

The use of lead in solder has been

controversial due to its potential toxicity and environmental impact. However,

lead has a lower melting point than tin and helps to improve the flow and wetting

properties of the solder. It is also less expensive than tin, which makes it a

popular choice for many soldering applications.

Why is Sn63Pb37 Solder Bar suitable for Wave Soldering?

One reason is that Sn63Pb37 solder has a

relatively low melting point of 183°C, which makes it easier to melt and work

with. This is important in wave soldering, as the process involves heating theleaded solder bar to its melting point and then allowing it to flow over the

components being soldered.

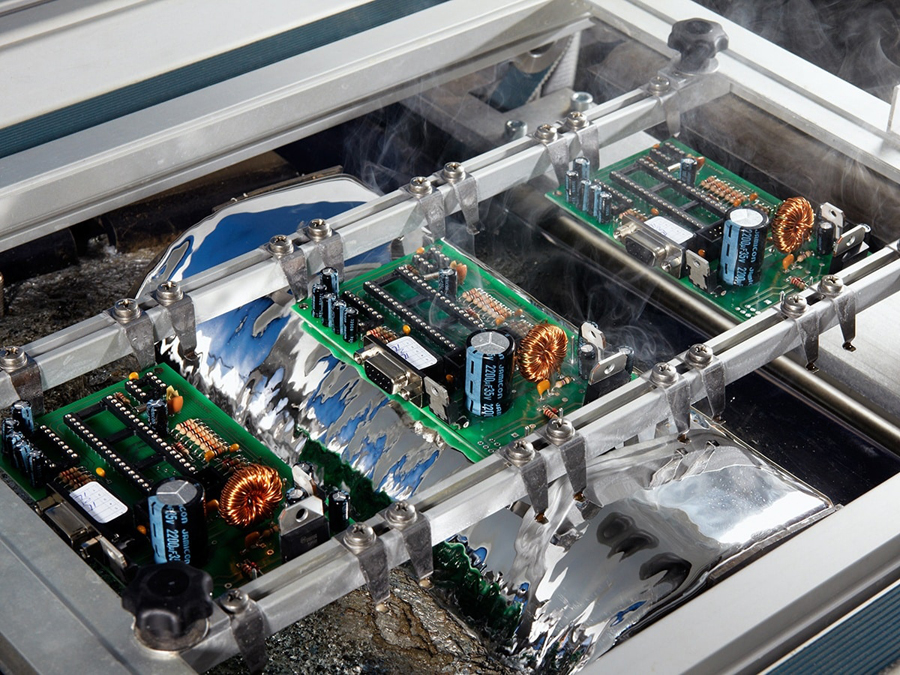

Wave soldering is a method of soldering

that is commonly used in the electronic manufacturing industry. It involves

using a wave of molten solder to flow over the components being soldered, which

helps to ensure that all of the joints are properly soldered. The components

are placed onto a circuit board and then passed through a wave of molten

solder, which is heated to the appropriate temperature. The solder is then

allowed to cool, forming strong and reliable connections between the components

and the circuit board.

What should we pay attention to when using Sn63Pb37 Solder Bar suitable for Wave Soldering?

There are a few things to consider when

using Sn63Pb37 solder bar for wave soldering. One is to ensure that the

components being soldered are properly prepared. This includes cleaning the

surfaces to be soldered and applying any necessary flux to help the solder flow

and wet the surfaces. It is also important to use the correct soldering

temperature, as overheating the solder can cause it to become brittle and

weaken the joint. And during the melting of solder bar, generally the surface

of the pot will have a little bit dross, these dross must be cleaned away

before we carry on with the wave soldering process.

Another consideration is the use of proper

soldering technique. It is important to apply the solder evenly and to avoid

creating any voids or gaps in the joint. Proper technique can help to ensure

that the joints are strong and reliable, and that the circuit board is fully

functional.

In addition to these considerations, it is

important to be aware of the environmental impact of leaded solder bar. For

some countries, there are ROHS regulation that doesn’t allow leaded solder bar

to be used, in this case it’s a must to use lead free solder bar.

And It is important to use proper

ventilation and safety equipment when working with leaded solder bar, and to

dispose of it properly to prevent it from entering the environment.

In summary, Sn63Pb37 leaded tin solder bar

is a popular choice for wave soldering due to its low melting point and good

flow and wetting properties. It is important to consider the proper preparation

of the components, the correct soldering temperature, and proper technique when

using this type of solder. It is also important to be aware of the potential

environmental impact of lead and to handle and dispose of it properly.

If you are looking for a supplier of Solder bar, please contact our sales team. Email: xfsolder@gmail.com or xfsolder@163.com , Whatsapp/Wechat: 008613450770997