ROHS Compliant Non Lead Tin Silver Solder 500g

ROHS Compliant Non Lead Tin Silver Solder 500g: A Professional Solution for Safe and Reliable Soldering

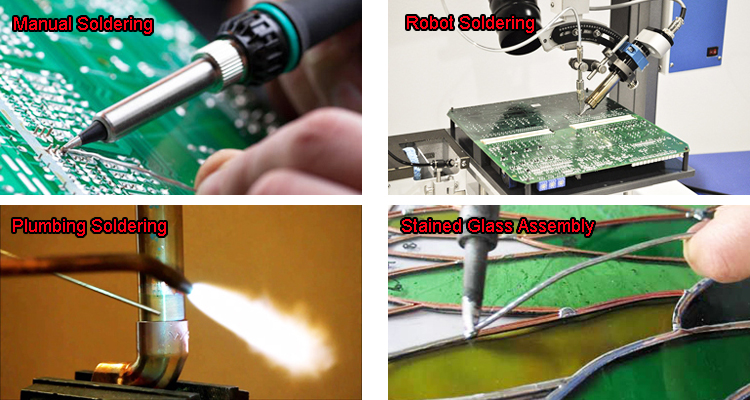

Soldering is a fundamental process in the electronics industry, used to join two or more metal parts together. It is essential to ensure that the solder used is safe, reliable, and environmentally friendly. This is where ROHS compliant non lead tin silver solder 500g comes into play. The non lead solder can be in the forms of solder wire, solder bar or solder paste. The different types are used for different ways of soldering technology.

What is Tin Silver Solder and its types?

Tin silver solder is a type of solder that contains tin and silver as the primary components. It is a popular choice for electronics and electrical applications due to its excellent electrical conductivity, corrosion resistance, and high melting point. The silver inside the solder is to help solder joints to be firm, leakage free, higher electrical conductivity. Tin silver solder is available in different types, such as Sn96.5Ag30.5 solder, Sn99Ag0.3Cu0.7 solder, Sn99.3Cu0.7 solder, Sn42Bi58 solder etc. And generally they are packed into 500g each unit. Like paste solder 500g per jar, wire solder 500g per roll etc.

Why Use Non Lead Tin Silver Solder?

Lead is a toxic substance that can cause severe health problems, such as neurological damage, developmental delays, and reproductive issues. Therefore, the use of lead-based solder has been limited or monitor in many countries, including the European Union and the United States. Non lead solder is a safer and more environmentally friendly alternative to lead-based solder. Especially some electronics products that need to comply with RoHS standards, then only non lead tin silver solder can be used.

Applications of Non Lead Tin Silver Solder:

ROHS compliant non lead tin silver solder 500g is suitable for a wide range of applications, including electronics, electrical, plumbing, and automotive industries. It is ideal for soldering components such as circuit boards, wires, and pipes. The solder is easy to use, and it provides a strong and reliable joint that can withstand mechanical stress and temperature changes.

Comparison between Non Lead Tin Silver Solder to Lead Solder:

The primary difference between lead and non lead solder is the composition. Lead-based solder contains lead, while non lead solder contains other metals such as tin, silver, and copper. Non lead solder has a higher melting point than lead-based solder, which makes it more suitable for high-temperature applications. Additionally, non lead solder is less prone to cracking and fatigue, which ensures a longer lifespan of the solder joint.

In conclusion, ROHS compliant non lead tin silver solder 500g is a professional solution for safe and reliable soldering. It is a non-toxic and environmentally friendly alternative to lead-based solder, making it the ideal choice for industries that prioritize safety and sustainability. With its excellent electrical conductivity, corrosion resistance, and high melting point, this solder is a must-have for any professional soldering application.

If you need to buy Non lead tin silver solder 500g from China, please contact our sales team, Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 0086 13450770997

Hits: 【Print】