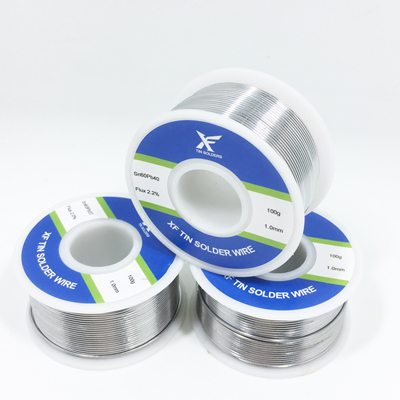

Sn60Pb40 Flux Core Lead Wire Solder for Electronics

Sn60Pb40 Flux Core Lead Wire Solder for Electronics

Sn60Pb40 flux core lead wire solder for electronics is a popular choice for those who work with electronics. This type of lead core solder is made up of tin and lead, with a activated rosin flux core that helps to remove any impurities and create a strong bond between the components being soldered. In this article, we will discuss what flux core wire solder Sn60Pb40 is, its specifications, features, advantages, uses, and how to use it effectively.

What is Flux Core Wire Solder Sn60Pb40?

Flux core solder Sn60Pb40 is a type of solder wire that is used in electronics. It is made up of 60% tin and 40% lead, with a flux core that helps to remove any impurities and create a strong bond between the components being soldered. When using the flux core solder for electronics, there is no need to apply seperate flux, as the core wire solder already contains flux.

Specifications of Sn60Pb40 Flux Core Lead Wire Solder for Electronics:

The specifications of flux core wire solder Sn60Pb40 include its composition, melting point, and diameter. As mentioned earlier, it is made up of 60% tin and 40% lead, with a flux core that helps to remove any impurities. Its melting point is around 183°C to 190℃ (361°F), which makes it ideal for use in applications where medium temperatures are required. The diameter of the wire can vary depending on the application, but it is typically between 0.5mm and 3mm. And for each spool of solder wire, we can make it from 50g per spool, 100g per spool, 200g per spool, up to 1kg per spool. We also customize to make big spool like 5kgs, 10kgs, 15kgs etc.

Advantages of Sn60Pb40 Flux Core Lead Wire Solder for Electronics:

There are several advantages to using Sn60Pb40 flux core solder for electronics. One of the main advantages is its medium melting point, which makes it ideal for use in applications where medium temperatures are required. It also has a flux core that helps to remove any impurities and create a strong bond between the components being soldered. Additionally, it is easy to use and can be used with a variety of different soldering irons. Another advantage is that it is readily available and affordable, making it a popular choice for those who work with electronics.

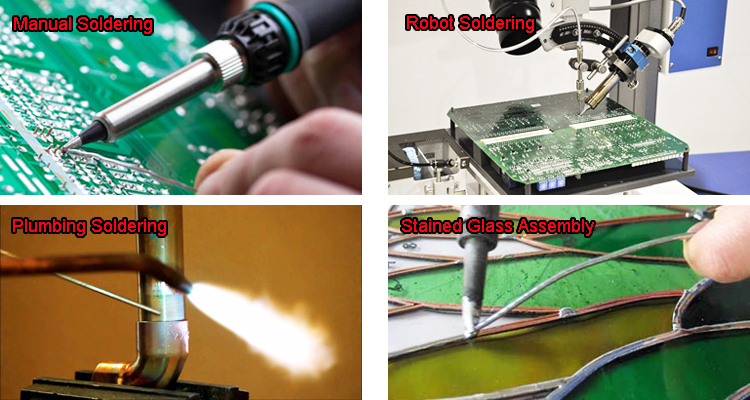

Uses of Sn60Pb40 Flux Core Lead Wire Solder:

Flux core wire solder Sn60Pb40 is commonly used in the electronics industry for a variety of applications. It is often used to solder components onto printed circuit boards (PCBs), as well as for wiring and cable assemblies. It is also used in the automotive industry for soldering electrical connections, as well as in the aerospace industry for soldering components onto circuit boards.

How to Use Sn60Pb40 Flux Core Lead Wire Solder for Electronics?

To use lead core solder Sn60Pb40, you will need a soldering iron, a soldering stand, and a pair of pliers. Begin by heating up the soldering iron and cleaning the components that you will be soldering. Next, apply a small amount of flux to the components to help remove any impurities. Then, place the lead core solder onto the components and heat it up with the soldering iron until it melts and creates a strong bond. Finally, use the pliers to hold the components in place until the solder cools and hardens.

In conclusion, flux core wire solder Sn60Pb40 is a popular choice for those who work with electronics. Its neduyn melting point, flux core, and ease of use make it ideal for a variety of applications in the electronics industry. By following the steps outlined above, you can effectively use flux core wire solder Sn60Pb40 to create strong and reliable connections between components.

If you need to buy flux core lead wire solder for electronics from China, please contact us. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 0086 13450770997

Hits: 【Print】