SAC305 High Temperature Silver Solder Paste for SMD Components

SAC305 High Temperature Silver Solder Paste for SMD Components

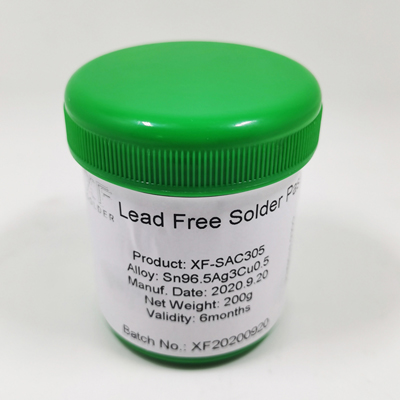

SAC305 high temperature silver solder paste is a popular choice for surface mount device (SMD) components due to its excellent thermal and electrical conductivity. This type of solder paste is composed of 96.5% tin, 3% silver, and 0.5% copper, making it an ideal choice for high-temperature applications. The melting point is around 225℃. And it's a grey paste in appearance, consisted of flux greese and tin powder size along with additive binders. Generally this high temp solder paste packed in jars or syringes.

Benefits of SAC305 High Temperature Silver Solder Paste for SMD Components

One of the primary benefits of SAC305 high temp silver solder paste is its high melting point at around 225℃. This makes it an ideal choice for applications that require high-temperature resistance, such as those found in the automotive and aerospace industries. Additionally, SAC305 high temperature solder paste is known for its excellent wetting properties, which allow it to flow easily and evenly across the surface of the SMD component. And adding silver to the process of soldering helps produce smooth, leak-tight, electrically conductive, and corrosion-resistant joints. Finally, this solder paste for SMD components is a lead free solder paste, complying with RoHS regulation, suitable to be used for products that need to comply with lead free standards.

Features of SAC305 High Temperature Silver Solder Paste for SMD Components

SAC305 high temp silver solder paste is a no-clean flux, which means that it does not leave any residue after soldering. This is an important feature for SMD components, as any residue left behind can interfere with the performance of the device. Additionally, SAC305 high temp solder paste is available in a variety of particle sizes, making it suitable for a wide range of applications. The standard powder sizes are T3 & T4。

How to Use SAC305 High Temperature Silver Solder Paste for SMD Components

Using SAC305 solder paste for SMD components is relatively straightforward. First, the paste should be applied to the pads on the PCB using a stencil or dispenser. Next, the SMD component should be placed onto the paste, and the entire assembly should be heated to the appropriate temperature to melt the solder. Once the solder has melted, it will flow evenly across the surface of the component, creating a strong and reliable bond. The soldering process generally is done by reflow oven or hot air gun.

Tips for Using SAC305 High Temperature Silver Solder Paste for SMD Components

When using SAC305 high temperature solder paste for SMD components, it is important to follow a few key tips to ensure the best results. First, the paste should be stored in a cool, dry place to prevent it from drying out or becoming contaminated. Additionally, the paste should be applied evenly to the pads on the PCB to ensure a strong bond. Finally, it is important to use the appropriate temperature and heating time to melt the solder and avoid damaging the SMD component.

In conclusion, SAC305 solder paste is an excellent choice for SMD components due to its high-temperature resistance, excellent wetting properties, and no-clean flux. By following the tips outlined above, you can ensure that your SMD components are soldered reliably and efficiently using SAC305 high temperature silver solder paste.

If you need to buy SAC305 high temperature temp silver solder paste for smd components, please contact us. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 0086 13450770997

Hits: 【Print】