China Bar Solder Lead Free for Electronics

Bar Solder Lead Free: The Future of Soldering

Soldering is an essential process in many industries, from electronics to plumbing. It involves joining two metal surfaces by melting a filler metal, known as solder, and allowing it to flow into the joint. However, traditional solder contains lead, a toxic substance that poses health and environmental risks. In response, the industry has developed lead-free alternatives, including bar solder lead free.

What are Bar Solder Lead Free for Electronics?

Bar solder lead free is a type of solder that does not contain lead. Instead, it uses a combination of metals, such as tin, silver, and copper, to achieve the desired properties. These metals are chosen for their low melting points, good wetting ability, and mechanical strength. Bar solder lead free is available in various compositions, each tailored to specific applications and requirements. The major compositions of bar solder lead free are: Sn96.5Ag3Cu0.5 bar solder, Sn99Ag0.3Cu0.7 bar solder & Sn99.3Cu0.7 bar solder. The higher percentage of silver inside, the higher cost the solder will be, but silver adds the benefits of better electrical conductivity & more resistance to thermal circulation.

Benefits of China Bar Solder Lead Free for Electronics

One of the main advantages of bar solder lead free is its compliance with environmental regulations. Lead is a hazardous substance that can contaminate soil, water, and air. It can also cause health problems, such as anemia, nerve damage, and developmental disorders. By using lead-free solder, manufacturers can reduce their impact on the environment and protect their workers and customers from harm.

Another benefit of bar solder lead free is its compatibility with modern electronics. Lead-free solder is less prone to forming brittle intermetallic compounds, which can cause cracks and failures in electronic components. It also has a higher melting point than traditional solder, which makes it more suitable for high-temperature applications. Moreover, lead-free solder is less likely to cause corrosion or oxidation, which can affect the performance and lifespan of electronic devices.

However, using bar solder lead free requires some adjustments in the soldering process. Lead-free solder requires higher temperatures and longer dwell times than traditional solder. It also requires a different flux, which is a chemical agent that helps the solder flow and bond to the metal surfaces. Therefore, manufacturers and technicians need to be trained and equipped with the proper tools and materials to work with lead-free solder.

China Bar Solder Lead Free for Electronics:

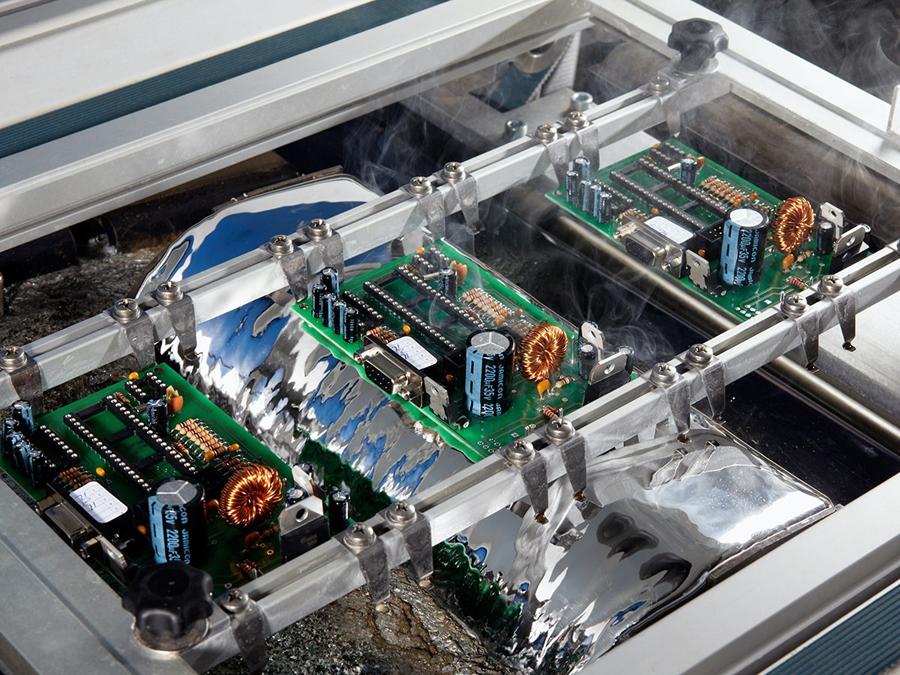

The using of bar solder for electronics are mainly done by dip soldering (a manual operation) & wave soldering (higher productivity with wave soldering machine).

In conclusion, bar solder lead free is a promising alternative to traditional solder that offers environmental, health, and performance benefits. By using lead-free solder, manufacturers can comply with regulations, improve product quality, and reduce risks to workers and customers. However, the transition to lead-free solder requires careful planning, training, and investment. As the industry moves towards a more sustainable and responsible future, bar solder lead free will play a crucial role in shaping the soldering landscape.

If you need to buy China Bar Solder Lead Free for Electronics, please contact our sales team. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 0086 13450770997