Bga Reballing Solder Paste for IC soldering

BGA Reballing Solder Paste for IC Soldering: A Professional Solution

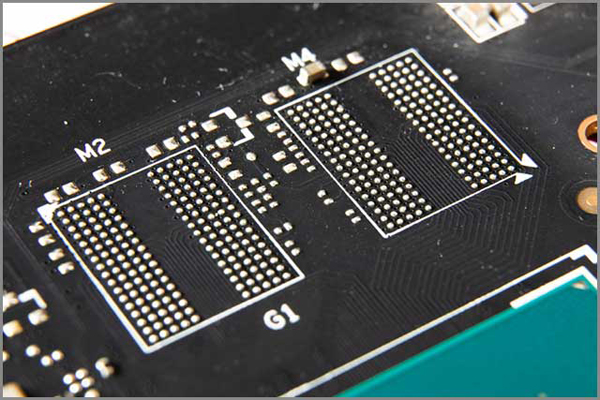

BGA (Ball Grid Array) reballing is a critical process in the electronics industry, where solder balls are replaced on the IC (Integrated Circuit) package. The reballing process is essential for repairing or upgrading the IC package, and it requires a high level of precision and accuracy. The success of the reballing process depends on the quality of the solder paste used for the IC soldering. BGA reballing solder paste is a professional solution that ensures the reliability and durability of the IC package.

BGA reballing solder paste is a type of flux that is used to attach the solder balls to the IC package. The IC soldering paste is made up of a mixture of metal powders, flux, and other additives. The metal powders provide the necessary conductivity, while the flux helps to remove any oxide layers and contaminants from the surface of the IC package. The additives in the paste help to improve the wetting and spreading properties of the solder, ensuring that it adheres to the IC package uniformly.

The quality of the BGA reballing paste is critical for the success of the reballing process. The paste must have the right viscosity, which is the measure of its thickness and flowability. The viscosity of the reballing solder paste should be such that it allows the solder balls to adhere to the IC package without flowing excessively. The paste should also have a good wetting property, which means that it should spread evenly on the surface of the IC package. The paste should also have a low level of voiding, which is the formation of air pockets in the solder joint. Voiding can lead to poor electrical conductivity and reduced reliability of the IC package.

Solder paste for reballing is available in different types, depending on the type of metal powders used. The most common types of metal powders used in the paste are tin-lead (Sn-Pb) and lead-free (Pb-free) alloys. The choice of the metal powder depends on the application and the specific requirements of the IC package. Tin-lead alloys are commonly used in applications where high reliability and long-term stability are required. Lead-free alloys are used in applications where environmental concerns and regulations require the use of non-toxic materials.

In conclusion, BGA reballing solder paste is a professional solution for IC soldering that ensures the reliability and durability of the IC package. The paste is made up of a mixture of metal powders, flux, and other additives that provide the necessary conductivity, wetting, and spreading properties. The quality of the paste is critical for the success of the reballing process, and it should have the right viscosity, wetting property, and low level of voiding. BGA reballing solder paste is available in different types, depending on the application and the specific requirements of the IC package.

If you need to buy Bga Reballing Solder Paste for IC soldering from China, please contact us. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 0086 13450770997

Hits: 【Print】