RMA No Clean Soldering Solder Paste for IC Chip

RMA No Clean Soldering Solder Paste for IC Chip

As the electronics industry continues to grow, the demand for high-quality soldering materials also increases. One of the most important components in electronic manufacturing is the solder paste, which is used to connect the IC chip to the printed circuit board (PCB). RMA No Clean Soldering Solder Paste is a popular choice for many manufacturers due to its excellent performance and reliability. In this article, we will introduce the product, its specifications, features, and how to use it for IC chip soldering.

Product Introduction of RMA No Clean Soldering Solder Paste for IC Chip

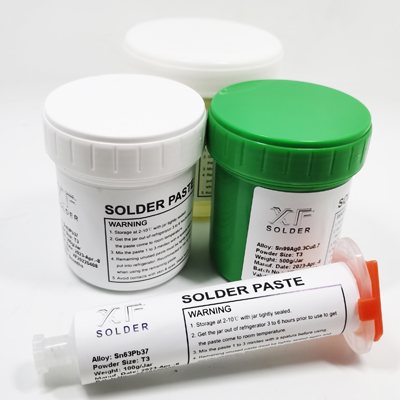

Soldering Solder Paste is a type of solder paste that is designed for use in electronics manufacturing. It is a rma no clean solder paste that is suitable for use with a wide range of IC chips and PCBs. The paste is made from a blend of high-quality metal alloys and flux, which ensures excellent soldering performance and reliability.

The RMA No Clean Soldering Solder Paste has the following specifications:

- Alloy: Sn63Pb37 solder paste or other alloys

- Flux type: RMA (Rosin Mildly Activated)

- Melting point: 183°C

- Particle size: Type 3 (20-45 microns) Type 4 (20-38 microns)

- Shelf life: 6 months

Features of RMA No Clean Soldering Solder Paste for IC Chip

The RMA No Clean Solder Paste has several features that make it an excellent choice for IC chip soldering:

1. Excellent wetting ability: The solder paste for ic chip has excellent wetting ability, which ensures that the solder joint is strong and reliable.

2. No-clean formula: The rma no clean formula of the solder paste means that there is no need to clean the PCB after soldering, which saves time and reduces the risk of damage to the PCB.

3. Low voiding: The solder paste has low voiding, which means that there are fewer air pockets in the solder joint, resulting in a stronger and more reliable connection.

4. Consistent performance: The solder paste has consistent performance, which ensures that the soldering process is reliable and repeatable.

How to RMA No Clean Solder Paste for IC Chip Soldering

Here are the steps to follow when using RMA No Clean Soldering Solder Paste for IC chip soldering:

1. Prepare the PCB: Clean the PCB thoroughly to remove any dirt, dust, or debris. Apply a small amount of flux to the pads where the IC chip will be soldered.

2. Apply the solder paste: Apply a small amount of solder paste to the pads where the IC chip will be soldered. Use a stencil or a syringe to apply the paste.

3. Place the IC chip: Place the IC chip on the pads where the solder paste has been applied. Make sure that the chip is aligned correctly.

4. Reflow the solder: Reflow the solder by heating the PCB to the melting point of the solder paste. Use a reflow oven or a hot air gun to heat the PCB.

5. Inspect the solder joint: Inspect the solder joint to ensure that it is strong and reliable. Use a microscope or a magnifying glass to inspect the joint.

Tips for Using RMA No Clean Soldering Solder Paste

Here are some tips for using RMA No Clean Soldering Solder Paste:

1. Store the solder paste in a cool, dry place to ensure its shelf life.

2. Use a stencil or a syringe to apply the solder paste for accurate and consistent results.

3. Use the correct amount of solder paste to avoid excess or insufficient solder.

4. Ensure that the IC chip is aligned correctly before reflowing the solder.

Conclusion

RMA No Clean Soldering Solder Paste is an excellent choice for IC chip soldering due to its excellent performance, reliability, and ease of use. Its no-clean formula, low voiding, and consistent performance make it a popular choice for many electronics manufacturers. By following the tips and steps outlined in this article, you can ensure that your IC chip soldering process is reliable and repeatable.

If you need to buy RMA No Clean Soldering Solder Paste for IC Chip from China, please contact us. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp / Wechat: 0086 13450770997

Hits: 【Print】