Soldering Paste 63 37 Tin Lead 50g

Soldering Paste 63 37 Tin Lead 50g: Full Detail & Technical Data

Soldering paste is a crucial component in the electronics industry, used to join two or more metal components together. Soldering paste 63 37 is a popular choice among manufacturers and hobbyists alike, thanks to its high-quality composition and ease of use. In this article, we will explore the technical data of soldering paste 63 37, its advantages, applications, and instructions for use.

Technical Data of Soldering Paste 63 37 Tin Lead 50g

Soldering paste 63 37 tin lead is made up of 63% tin and 37% lead, which gives it a melting point of 183°C. It is a eutectic alloy, meaning it has a single melting point and solidifies quickly, making it ideal for mass production. The paste is also flux-cored, which means it contains a flux that helps to clean the surface of the metal and promote better adhesion. Generally we pack soldering wire 50g each syringe for DIY or repairing projects.

Advantages of Soldering Paste 63 37 Tin Lead 50g

One of the primary advantages of soldering paste 63 37 is its low melting point, which makes it suitable for use with heat-sensitive components. It also has excellent wetting properties, which means it spreads evenly over the surface of the metal and creates a strong bond. Additionally, soldering paste 63 37 has a long shelf life, making it a cost-effective choice for manufacturers.

Applications of Soldering Paste 63 37 Tin Lead 50g

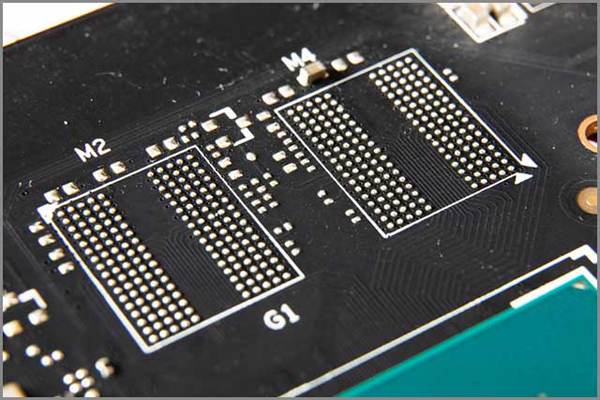

Soldering paste 63 37 tin lead is commonly used in the electronics industry for a variety of applications, including surface mount technology (SMT), through-hole technology (THT), and rework. It is also used in the automotive industry for repairs and maintenance. The paste is suitable for use with a range of metals, including copper, brass, and nickel.

Instructions for Using Soldering Paste 63 37 Tin Lead 50g

To use soldering paste 63 37 tin lead, you will need a soldering iron, a heat source, and a clean surface to work on. Begin by cleaning the surface of the metal with a wire brush or sandpaper to remove any dirt or debris. Apply a small amount of soldering paste to the joint, making sure to cover the entire surface. Heat the joint with the soldering iron until the paste melts and flows into the joint. Allow the joint to cool and solidify before handling.

In conclusion, soldering paste 63 37 is a high-quality, versatile, and cost-effective choice for manufacturers and hobbyists alike. Its low melting point, excellent wetting properties, and long shelf life make it ideal for a range of applications in the electronics and automotive industries. By following the instructions for use, you can achieve strong, reliable bonds between metal components.

If you need to buy Soldering Paste 63 37 Tin Lead 50g from China, please contact us. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp / Wechat: 0086 13450770997

Hits: 【Print】