1.6mm 400gm Tin Solder Wire 35 65

1.6mm 400gm Tin Solder Wire 35 65

Solder wire is a critical component in

electronic circuitry and electrical engineering. It is used to bond electronic

components together and create connections between different parts of a

circuit. The quality of the solder wire can have a significant impact on the

overall quality and reliability of the circuit. In this article, we will be

introducing our 1.6mm 400gm tin solder wire 35 65, and examining its features

and benefits in detail.

Product Description of 1.6mm 400gm Tin Solder Wire 35 65:

Our 1.6mm 400gm tin solder wire 35 65 is a

medium quality solder wire with very affordable price, that is ideal for a wide range of applications. It is

made from a carefully balanced blend of tin and lead, with a composition of 35%

tin and 65% lead. It is also known as tin solder wire Sn35Pb65. This composition provides a number of advantages over other

solder wires on the market, including improved conductivity, better wetting

properties, reduced brittleness and lower costs.

Technical Specifications of 1.6mm 400gm Tin Solder Wire 35 65:

Diameter: 1.6mm

Composition: 35% tin, 65% lead

Melting Point: 183 to 247°C

Flux: Rosin Core

Weight: solder wire 400gm

Performance Characteristics of 1.6mm 400gm Tin Solder Wire 35 65:

Our solder wire 400gm offers a number of performance benefits that make it an excellent choice for a wide range of soldering applications. Some of these benefits include:

1. Improved Wetting Properties: The composition of tin solder wire 35 65 allows it to flow more easily and evenly over the surfaces being soldered, resulting in better wetting and stronger bonds.

2. High Conductivity: The tin and lead composition of our solder wire provides excellent conductivity, ensuring that electrical signals are transmitted accurately and efficiently.

3. Reduced Brittleness: Our solder wire 400gm has been carefully formulated to reduce brittleness, making it less likely to crack or break during use.

4. Excellent Flux Properties: Our solder wire

features a rosin core flux, which provides excellent wetting and cleaning

properties, ensuring a clean and reliable joint.

5. Low cost: The solder wire 1.6mm has a much lower price comparing to solder wire 63 37 or lead free solder wire. Making it affordable to some medium quality requirements job.

Applications of 1.6mm 400gm Tin Solder Wire 35 65:

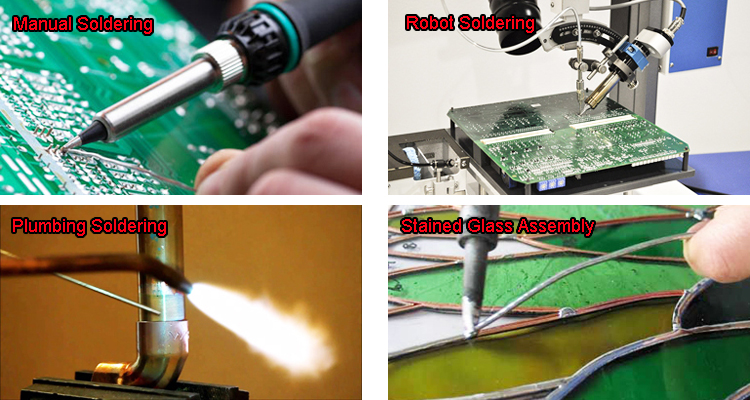

Our 1.6mm 400gm tin solder wire 35 65 is suitable for a wide range of applications, including:

1. Electrical Engineering: Our solder wire 400gm is ideal for use in electrical engineering applications, such as circuit board assembly, component attachment, and wire bonding.

2. Electronic Repair: Our solder wire 1.6mm is also perfect for repairing electronic devices, such as smartphones, laptops, and game consoles.

3. Plumbing: Our tin solder wire 35 65 can also be used

for plumbing applications, such as soldering copper pipes.

Packaging of 1.6mm 400gm Tin Solder Wire 35 65:

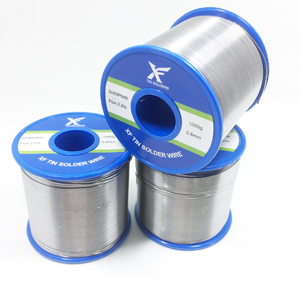

Our 1.6mm 400gm tin solder wire 35 65 is

available in a variety of packaging options, including spools and reels. The

packaging is designed to protect the solder wire from damage during storage and

transport, ensuring that it arrives in perfect condition when it is needed.

Usage Guidelines of 1.6mm 400gm Tin Solder Wire 35 65:

When using our solder wire, it is important

to follow some simple usage guidelines to achieve the best results. First,

ensure that the surfaces to be joined are clean and free from any contaminants

such as oil or grease. Next, preheat the surfaces to be joined to ensure that

the solder melts and flows properly. It is also important to avoid overheating

the solder wire as this can cause it to break or produce poor quality joints.

Safety Guidelines:

While using any type of soldering wire, it is important to follow some basic safety guidelines to prevent any accidents or injuries. Here are some guidelines to keep in mind while using 1.6mm 400gm tin solder wire 35 65:

1. Wear protective gear: Always wear protective gear such as safety glasses, gloves, and a mask while soldering. This will help prevent burns, cuts, and inhaling harmful fumes.

2. Keep the work area clean and organized: A cluttered work area can lead to accidents and injuries. Make sure to keep your work area clean and organized.

3. Keep the soldering iron and wire away from flammable materials: The high temperatures produced by the soldering iron can easily ignite flammable materials. Keep the soldering iron and wire away from any flammable materials.

4. Use a soldering iron stand: A soldering

iron stand can prevent the soldering iron from falling over and causing damage

or injury.

If you need to buy 1.6mm 400gm Tin Solder Wire 35 65 from China, please contact us. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsaspp/Wechat: 0086 13450770997