China solder wire factory

China Solder Wire Factory

As generally Solder wire is just a solder accessory or solder consumable, just like a screw to a big machine, which is just a very small stuff like nobody, so maybe we know about it's finished product but we don't know how it's produced in a China solder wire factory and how is the solder wire factory looks like. That's what we would like to share with you today, we will take our own solder wire factory in China as example to introduce to you.

What equipment does a China solder wire factory have and what function does each of them do?

1. Melting Pot. This is used to melt down the ingots of Tin, Lead, Silver, Copper etc depending on what alloys you're going to produce. But for leaded solder alloy and lead free alloy we have 2 separated melting pots in order not to pollute the lead free alloys with lead. When melting down the alloys, we melt the lead first and then add the tin in. During this process, the stir device of the machine will keep stiring the melted metal to make them well mixed together. And eventually the alloy is made into a round bar form as raw material.

2. Casting machine. This machine is to cast the round bar of solder alloy into a 10mm wire diameter. This is a semi-finished solder wire. And generally if you want to make the solder wire with rosin flux cored, in the China solder wire factory we will make it with a hollow core which eventually flux will be injected inside.

3. Drawing machine. This machine is to make the solder wire from a 10mm wire diameter into the requested wire diameter. Like in our own factory, we make the solder wire from 0.6mm to 2.5mm wire thickness.

4. Winding machine. As in the market, we see the solder wires come in a roll form, because in the solder wire factory in China we have winding machine to wind the finished solder wire into roll form at clients required weight. For example, 250g/roll, or 1000g/roll.

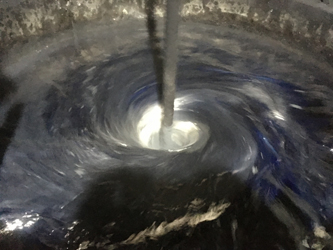

5. Rosin flux mixer. This device is to melt the rosin and adding flux and necessary additives needed into the rosin, and the mixed rosin flux will eventually inject into the solder wire core.

This is not a complex production process, thus you will find that most of the China solder wire factory is not very big.

And what solder wire alloy can the China solder wire factory produce:

Take ourselves XF Solder as example, we can produce below:

Leaded solder wire of:

Lead free solder wire of:

Our lead free solder wires comply with ROHS.

Contact us if you need any information, Email: xfsolder@gmail.com or xfsolder@163.com, Whatsapp/wechat: 008613450770997