solder wire electronics

Solder wire electronics

How different applications of solder wire?

1. Solder wire can be used for soldering of electronics. This is the most conventional use of solder products, which has long history over time. This type of solder wire needs to have good electrical conductivity as it's used to bond the electrical wire with electronic components.

2. Solder wire also can be used for soldering of metals. Like in Europe or North America, copper, stainless steel, zinc is used for roofing, flashing etc through seaming system and there's a joint to be sealed up, solder wire can be used to seal up these joints. And also for copper plumbing pipes, the joint between pipe and fittings plumbers will use the solder wire to seal up the joint.

3. Other application, such as solder wire used for soldering stained glass, as stained glass is assembled with lead or copper frame, the solder wire is used for soldering the frame.

How many types of solder wire for electronics?

Basically two types:

Lead free solder wire: majorly consisted of tin, silver, copper and free of lead content. This type of solder wire requires more heat to work with because melting point is higher than 217℃ ; And it's used to replace leaded solder wire in some applications where leaded solder wire is banned, such as home appliances which requires all components to be ROHS compliant.

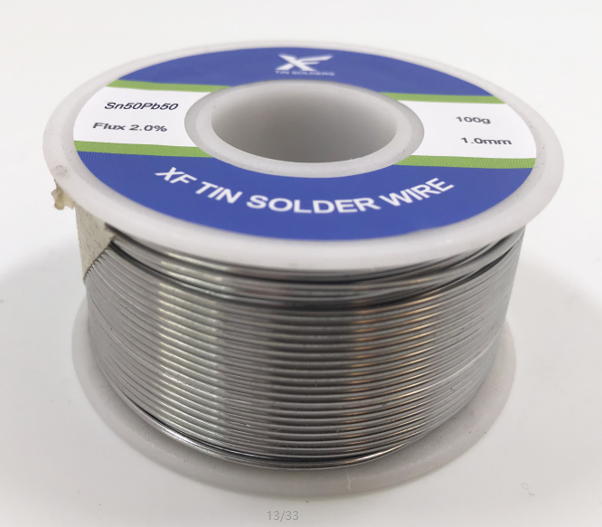

Tin lead solder wire: this type of solder wire is the most conventional type and still up to today is very frequently used. It's much cheaper than lead free solder wire and more easier to work with, easy to wet and flow, bonding strength is good. Only thing is when ROHS compliance is needed, this type of solder wire is not applicable.

If you need to import solder wire for electronics, contact us. Email: xfsolder@gmail.com ; xfsolder@163.com ; Whatsapp/Wechat: 008613450770997