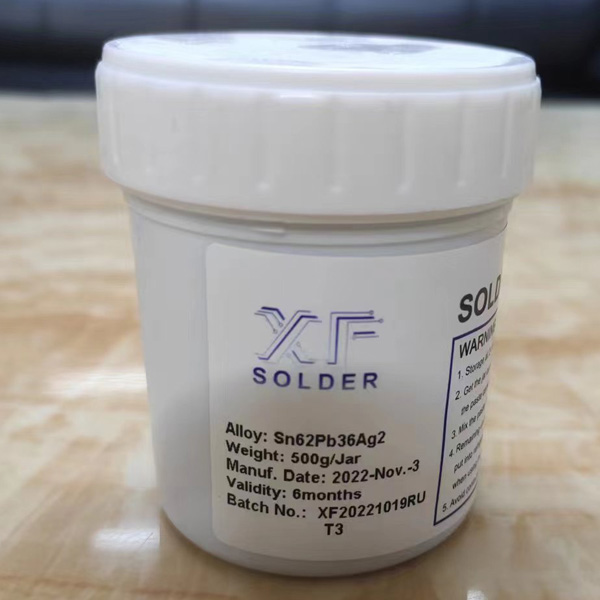

Leaded Tin Silver Solder Paste Sn62Pb36Ag2

Leaded Tin Silver Solder Paste Sn62Pb36Ag2

Basic Product Information of Leaded Tin Silver Solder Paste Sn62Pb36Ag2

Solder paste is a type of soldering

material that is used in the assembly of electronic components onto printed

circuit boards (PCBs). It is a key component in the process of surface mount

technology (SMT), which involves the placement of components onto the surface

of a PCB rather than through holes. Solder paste is a viscous mixture of fine

solder particles, flux, and a binder that holds the mixture together in a

paste-like form. It is applied to the PCB using a stencil and then heated to

melt the solder and create a strong, permanent connection between the

components and the PCB.

One popular type of solder paste is

Sn62Pb36Ag2, which is a eutectic alloy composed of 62% tin, 36% lead, and 2%

silver. Eutectic alloys have a unique melting point that is lower than the

melting point of any of their individual components, making them easy to melt

and work with. The Sn62Pb36Ag2 alloy has a melting point of 179°C, which makes

it ideal for use in SMT processes where the PCB and components are heated to

relatively low temperatures.

Benefits of Leaded Tin Silver Solder Paste Sn62Pb36Ag2:

There are several key features that make

Sn62Pb36Ag2 solder paste an attractive choice for many applications. One of the

main benefits is its high reliability and consistency. The addition of silver

to the alloy improves the overall performance and reliability of the solder

joint, and the eutectic nature of the alloy ensures that it melts and

solidifies at a consistent temperature every time. This can help to reduce the

risk of soldering defects, such as cold or insufficiently melted joints, which

can lead to reliability issues down the line.

Another key feature of Sn62Pb36Ag2 solder

paste is its good electrical conductivity. The combination of tin and lead in

the alloy creates a solder that has good electrical conductivity and low

resistance, which is important for ensuring efficient signal transmission and

power delivery in electronic devices. The addition of silver to the alloy also

helps to improve the conductivity and thermal performance of the solder.

Applications of Leaded Tin Silver Solder Paste Sn62Pb36Ag2:

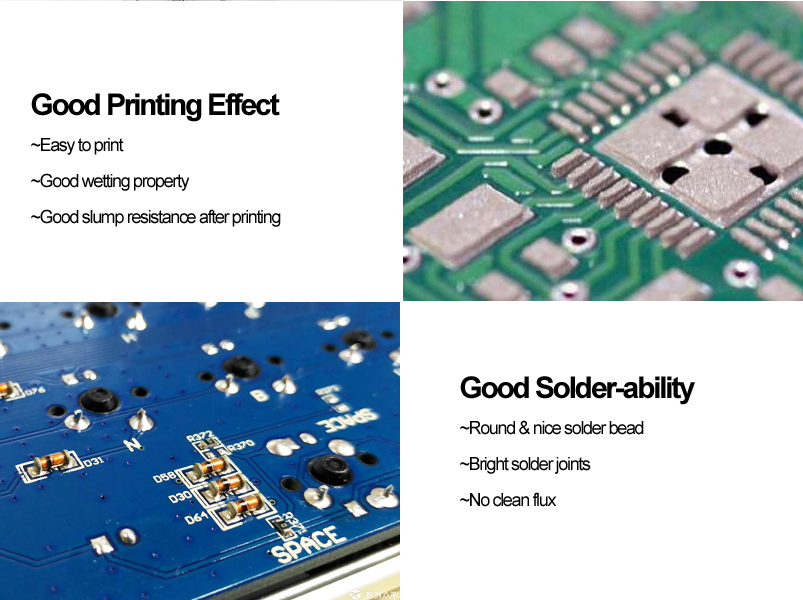

In terms of its application and use,

Sn62Pb36Ag2 solder paste is typically used in SMT processes for the assembly of

electronic components onto PCBs. It is applied to the PCB using a stencil,

which is a thin metal or polymer sheet with openings that correspond to the

locations of the components on the PCB. The stencil is placed over the PCB and

the solder paste is applied through the openings using a dispensing machine or

a manual squeegee. The PCB and components are then placed onto the paste, and

the entire assembly is heated to melt the paste and create the soldered

connections.

Technical Information of Leaded Tin Silver Solder

Paste Sn62Pb36Ag2:

The basic technical data for Sn62Pb36Ag2

solder paste includes its melting point, which as mentioned is 179°C, and its

viscosity, which is typically in the range of 10,000 to 50,000 centipoise (cP).

The viscosity of the paste can be adjusted by adding or removing flux or by

using different binder materials. Other technical data for Sn62Pb36Ag2 solder

paste includes its flow rate, which is a measure of how well it spreads and

conforms to the surfaces being soldered, and its wetting properties, which

refer to its ability to form a strong, reliable connection between the

components and the PCB.

In summary, Sn62Pb36Ag2 solder paste is a

reliable, high-performance soldering material that is widely used in the

assembly of electronic components onto PCBs. Its eutectic composition, good

electrical conductivity, and consistent melting point make it an excellent

choice for many SMT applications, and it is easy to use and apply to PCB.

Contact our sales team for more technical information or for a quote. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 008613450770997