Low Temperature Lead Free T3 Sn42Bi58 Tin Bismuth Solder Paste for PCB SMT Reflow Soldering

Low Temperature Lead Free T3 Sn42Bi58 Tin Bismuth Solder Paste for PCB SMT Reflow Soldering

Lead free T3 Sn42Bi58 tin bismuth solder paste is a popular choice for use in PCB and SMT soldering due to its strong bonding properties and low melting point. This type of solder paste is made from a mixture of tin bismuth powder, flux and other trace elements that are formulated to provide a strong and reliable bond at low temperatures. The tin bismuth powder sizes are available from T1 to T7, while most commonly used types are T3 solder paste or T4 solder paste. Powder size of T3 solder paste is from 25 to 45 microns, and powder size for T4 is 20 to 38 microns.

It is a lead free solder paste is a type of

solder paste that does not contain any lead, making it a more environmentally

friendly and safe choice for use in electronics manufacturing. And low

temperature of melting point at 138℃, making this solder

paste a good choice for use in soldering applications where the temperature may

be restricted or limited.

Thus, in our PCB and SMT soldering we should

choose the proper type of tin solder paste to create a strong bonding

properties and proper working temperature. Tin solder paste is available in a

variety of formulations to meet the specific needs and preferences of the user.

To use PCB solder paste we need to use SMT (surface

mount technology) to print the sn42bi58 solder paste on our PCB boards, by

using a stencil. And for small jobs, using hot air guns to conduct the

soldering process is good enough. While to achieve a more productive volume of

PCB soldering, reflow soldering is a better way. Reflow soldering is a process

in which the solder paste is applied to the PCB or SMT components, and then the

PCB or components are heated to a proper temperature to melt the solder paste

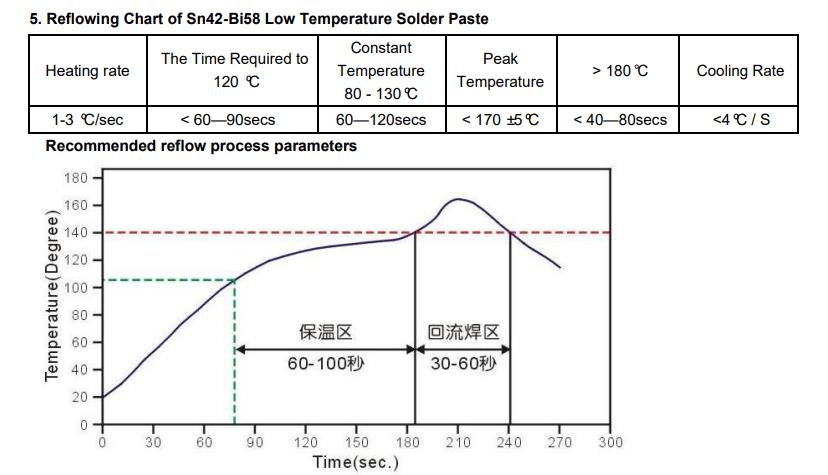

and create a strong and reliable bond. It’s important to follow up the reflowing

chart provided by the reflow paste manufacturer, so that the smt tin solder

paste can melt and solidify properly to bond between the PCB and the electronic

components, ensuring a stable and reliable connection.

Benefits of Low Temperature Lead Free T3 Sn42Bi58 Tin Bismuth Solder Paste for PCB SMT Reflow Soldering

Sn42Bi58 tin bismuth solder paste is its

ability to provide a strong and reliable bond at low temperatures. This is

particularly useful in soldering applications where the temperature may be

restricted or limited, as it allows for a strong and reliable bond to be formed

without the need for high heat. Some electronic components are temperature sensitive

and easily to be damaged by high temperature. Such a pcb paste can help to

reduce the risk of damaging the electronic components or the PCB during the

soldering process.

This type of T3 tin solder paste is with good

fluidity but with good viscosity. It is easy to work with and can be easily

applied to the PCB or SMT components during stencil printing. It is no clean

type bismuth solder paste, and requires no cleaning after soldering because there’s

just little, non-aggressive residue. Even in special cases, that you prefer to

clean the PCB after soldering, it is easy to clean up, as it can be easily

removed with a simple wiping action.

Sn42Bi58 solder paste is a lead free solder

paste. In some countries, leaded materials are not allowed to be used in

electronics. And in this case, during the EMS (electronics manufacturing), we must

use the lead free solder paste rather than leaded solder paste.

SMT tin solder paste meets the trend of

electronics manicuring development. Nowadays electronic products are designed

to be smaller and smaller, by using solder wire it’s very difficult to operate on

the PCB or electronic components. Thus, SMT manufacturing is introduced into

the electronics manufacturing, and tin solder made in a paste form can meet

such soldering work. T3 solder paste, its powder size can meet most general PCB

printing and soldering work.

What should we pay attention to when using low temperature lead free T3 Sn42Bi58 tin bismuth solder paste for PCB or SMT soldering?

It is important to follow the proper reflow

chart and process to ensure a strong and reliable bond. The reflow chart and

process will vary depending on the specific type of solder paste being used, as

well as the specific soldering application. However, generally speaking, the

following steps can be followed when using low temperature lead free T3

Sn42Bi58 tin bismuth solder paste for PCB or SMT soldering:

Preheat the PCB or SMT components: Before

applying the tin solder paste, it is important to preheat the PCB or components

to a temperature that is slightly below the melting point of the Sn42Bi58 solder

paste. This will help to ensure that the paste is able to flow smoothly and

form a strong and reliable bond.

Apply PCB solder paste: Once the PCB or

components have been preheated, the bismuth solder paste can be applied using

stencil printing. It is important to carefully apply the paste in a thin, even

layer, ensuring that it covers all of the areas that need to be soldered.

Place the SMT components: After the SMT tin

solder paste has been applied, the SMT components can be placed onto the PCB.

It is important to carefully align the components and ensure that they are

properly seated on the PCB.

Reflow the solder paste: Once the SMT

components are in place, the PCB or components can be heated to a temperature

that is slightly above the melting point of this lead free solder paste. This

will cause the paste to flow and form a strong and reliable bond between the

components and the PCB.

Cool and inspect: After the reflow process

is complete, the PCB or components should be allowed to cool to room

temperature. Once cooled, the bond between the components and the PCB can be

inspected to ensure that it is strong and reliable.

Overall, low temperature lead free T3 Sn42Bi58 tin bismuth solder paste is a popular choice for use in PCB and SMT soldering due to its strong bonding properties and low melting point, easy to clean up , easy to work with, environmentally friendly solder paste.

Contact our sales team, if you need to purchase this T3 Sn42Bi58 Solder Paste. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp / Wechat: 0086 13450770997