SAC305 SMD PPD Soldering Paste for Electronics

SAC305 SMD PPD Soldering Paste for Electronics

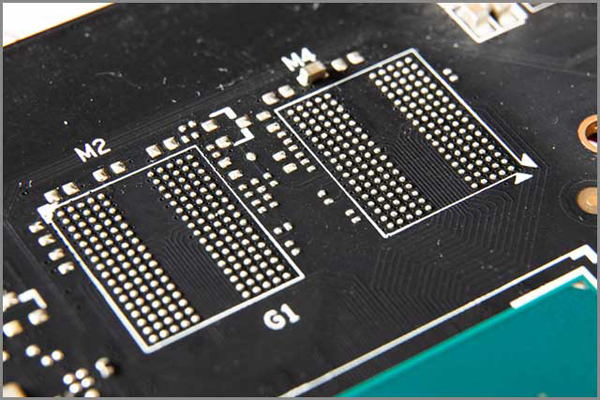

When it comes to electronics manufacturing, soldering is an essential process that ensures the components are firmly attached to the circuit board. Soldering paste is a critical component in this process, and SAC305 soldering paste is one of the most popular options available in the market. In this article, we will take a closer look at what SAC305 SMD PPD soldering paste.

What is SAC305 SMD PPD Soldering Paste?

SAC305 paste is a type of soldering paste that is commonly used in electronics manufacturing. SAC stands for Tin (Sn), Silver (Ag), and Copper (Cu), which are the primary elements that make up the soldering paste. The number 305 refers to the percentage of silver in the alloy, which is 96.5%. The remaining 3.0% is made up of silveer and 0.5% of copper. SMD stands for Surface Mount Device and indicates that the component is mounted on the surface of the circuit board in contrast to through-hole components which are mounted in holes, which is a type of stencil printing process used to apply the soldering paste.

Features and Specifications of SAC305 SMD PPD Soldering Paste:

SAC305 SMD PPD soldering paste has several features that make it an excellent choice for electronics manufacturing. One of the most significant advantages of this soldering paste is its high melting point, which is 217 to 220°C. This makes it suitable for use in high-temperature applications, such as automotive electronics and aerospace components.

Another advantage of SAC305 SMD PPD soldering paste is its excellent wetting ability. Wetting is the ability of the soldering paste to spread evenly over the surface of the component and the circuit board. SAC305 SMD PPD soldering paste has a high surface tension, which ensures that it spreads evenly and forms a strong bond.

SAC305 SMD PPD soldering paste also has a low voiding rate, which means that it forms fewer air pockets or voids during the soldering process. This is essential because voids can weaken the bond between the component and the circuit board, leading to reliability issues.

How to Use SAC305 SMD PPD Soldering Paste:

Using SAC305 SMD PPD soldering paste is relatively straightforward. The first step is to prepare the circuit board and the components by cleaning them thoroughly to remove any dirt, dust, or grease. Next, apply the soldering paste to the pads using a stencil or a dispensing tool. The amount of soldering paste applied should be just enough to cover the pad without overflowing.

After applying the soldering paste, place the components on the pads and heat the assembly using a reflow oven or a hot air gun. The heat causes the soldering paste to melt and form a strong bond between the component and the circuit board.

Storage Conditions of SAC305 SMD PPD Soldering Paste?

Proper storage of SAC305 SMD PPD soldering paste is crucial to ensure its effectiveness and longevity. The soldering paste should be stored in a cool, dry place, away from direct sunlight and heat sources. It should also be kept in an airtight container to prevent moisture and contaminants from entering.

Conclusion:

SAC305 SMD PPD soldering paste is an excellent choice for electronics manufacturing due to its high melting point, excellent wetting ability, and low voiding rate. It is easy to use and requires proper storage to maintain its effectiveness. By following the guidelines outlined in this article, you can ensure that your SAC305 SMD PPD soldering paste performs optimally and delivers reliable results.

If you need to buy SAC305 Soldering paste, please contact our sales team, Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 008613450770997