Sn63Pb37 IC Reballing Solder Paste

Sn63Pb37 IC Reballing Solder Paste: Everything You Need to Know

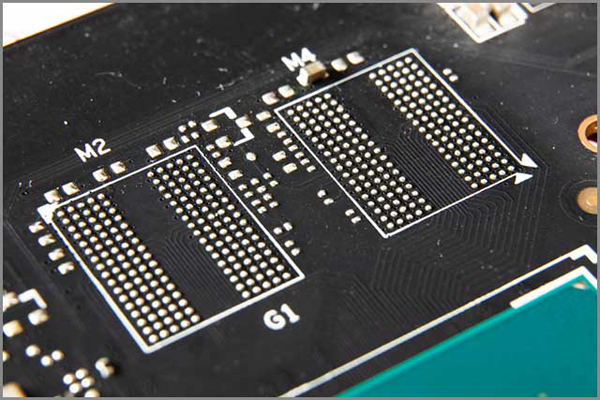

In the world of electronics, the process of reballing has become increasingly important. This process involves removing the existing solder balls from a component and replacing them with new ones. One of the most critical components of this process is the solder paste used. Sn63Pb37 IC reballing solder paste is one of the most popular choices for this process. In this article, we will explore what this solder paste is, what IC reballing is, the features of IC reballing paste, and how to use it.

What is Sn63Pb37 Solder Paste?

What is IC Reballing?

IC reballing is the process of removing the existing solder balls from a component and replacing them with new ones. This process is necessary when a component needs to be repaired or reworked. IC reballing is a delicate process that requires precision and skill. It involves removing the old solder balls, cleaning the component, applying new solder paste, and reflowing the component.

Features of IC Reballing Paste

How to Use Sn63Pb37 IC Reballing Paste?

Conclusion

Sn63Pb37 IC reballing solder paste is an excellent choice for the reballing process. It has several features that make it an ideal choice for this process, including good wetting properties, low oxide formation, good reflow properties, and consistent particle size. Using IC reballing paste requires precision and skill, but with the right tools and techniques, it can be done successfully. If you are looking for a reliable and effective solder paste for your reballing needs, Sn63Pb37 IC reballing solder paste is an excellent choice.

If you need to buy Sn63Pb37 IC Reballing Solder Paste, please contact our sales team, Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 008613450770997