Lead Free Solder Wire Tin

Lead Free Solder Wire Tin: A Safer Alternative for Electronics Manufacturing

Soldering is a crucial process in electronics manufacturing. It involves joining two metal parts using a filler metal, commonly known as solder. However, traditional solder wire contains lead, a toxic substance that poses health risks to both humans and the environment. As a result, the demand for lead-free solder wire tin has been increasing in recent years. In this article, we will introduce the product, its specification, core options and uses, why using lead-free, tips for using, and prices.

Product Introduction of Lead Free Solder Wire Tin

Lead free tin is a type of solder wire that is free from lead. It is made of a combination of tin, copper, and silver, which makes it a safer alternative to traditional leaded solder wire. The solder wire tin comes in various diameters, ranging from 0.5mm to 3mm, and is available in spools or reels, ranging from 50g to 1kg each. Lead free tin is also available in the forms of solder bar & solder paste.

The specification of lead free solder wire tin varies depending on the manufacturer. However, the most common compositions are 96.5% tin, 3% silver and 0.5% copper; 99% tin with 0.7% copper. The melting point of this solder wire is around 217°C, which is slightly higher than traditional solder wire. It also has good wetting properties, which means it can easily flow and bond with the metal parts.

Core Options and Uses of Lead Free Solder Wire Tin

Solder wire tin comes in two core options: rosin-core and water-soluble core. The rosin-core option is suitable for general-purpose soldering, while the water-soluble core is ideal for applications that require easy cleaning, such as medical devices and food processing equipment.

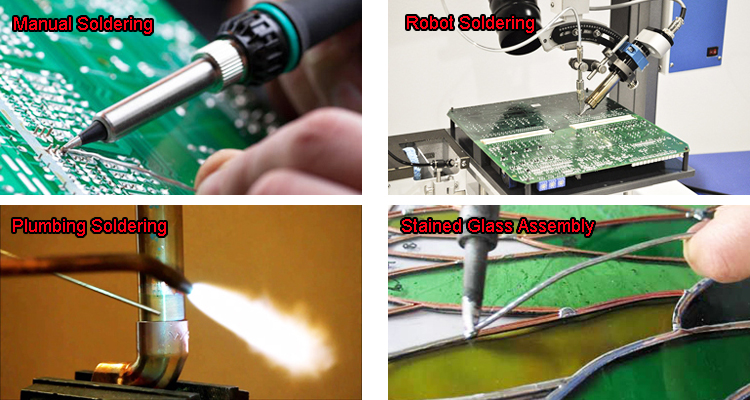

Lead free tin is used in various applications, including electronics manufacturing, plumbing, and automotive repair. It is suitable for soldering copper, brass, nickel, and stainless steel.

Why Using Lead Free Solder Wire Tin:

Lead is a toxic substance that can cause severe health problems, such as anemia, kidney damage, and neurological disorders. It is also harmful to the environment, as it can contaminate soil and water sources. Using lead-free solder wire tin eliminates these risks, making it a safer and more sustainable option.

Tips for Using Lead Free Solder Wire Tin:

When using solder wire tin, it is essential to follow the manufacturer's instructions carefully. Here are some tips to ensure a successful soldering process:

- Clean the metal parts thoroughly before soldering to ensure good bonding.

- Use the correct diameter of solder wire for the application.

- Apply heat evenly to avoid overheating or underheating the metal parts.

- Use flux to improve wetting and prevent oxidation.

Prices of Lead Free Solder Wire Tin

The price of lead free tin varies depending on the diameter, core option, and quantity. Generally, it is slightly more expensive than traditional solder wire. However, the cost difference is minimal compared to the health and environmental benefits.

Conclusion

Lead-free solder wire tin is a safer and more sustainable alternative to traditional solder wire. It is made of a combination of tin, copper, and silver and comes in various diameters and core options. It is suitable for various applications, including electronics manufacturing, plumbing, and automotive repair. By using lead-free solder wire tin, we can eliminate the health and environmental risks associated with lead. However, it is essential to follow the manufacturer's instructions carefully to ensure a successful soldering process.

If you need to buy lead free solder wire tin from China, please contact our sales team. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 0086 13450770997

Hits: 【Print】