0.3mm flux rosin core lead free wire tin solder for electronics

0.3mm Flux Rosin Core Lead Free Wire Tin Solder for Electronics

Soldering is an essential process in electronics that involves joining two metal components using a filler metal. One of the most popular types of solder is the rosin core lead-free wire tin solder, which is widely used in various electronic applications. In this article, we will discuss what rosin core lead-free wire solder is, why you should use 0.3mm tiny diameter, the alloy types, benefits of this product, applications, and advice for using.

What is Flux Rosin Core Lead Free Wire Tin Solder?

Flux osin core lead-free wire solder is a type of solder that contains a flux core made of rosin, a natural resin derived from pine trees. The rosin flux is used to clean and remove oxides from the metal surfaces being soldered, allowing the solder to flow and bond the metals together. And lead free wire solder is a tin based solder mixed with small portions of silver, copper, antimony, bismuth etc, it doesn't contain lead. This type of flux rosin core solder is a 2-in-1 product, the 0.3mm solder can be used directly for electronics manufacturing and there is no need to apply seperate flux.

Why do we need 0.3mm solder with such tiny diameter?

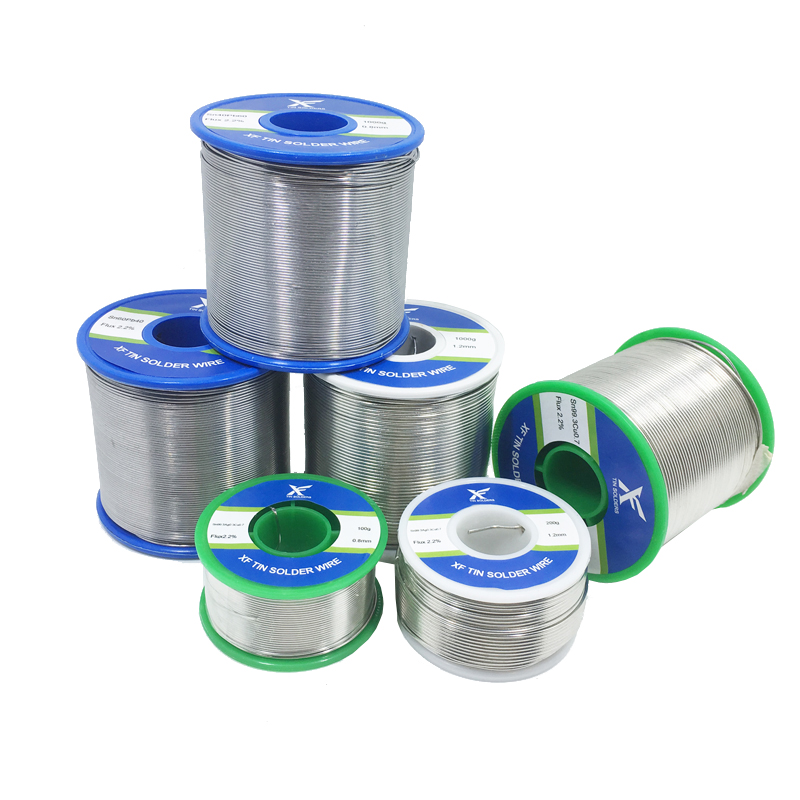

We produce the tin solder for electronics with many options of wire diameters. Common diameters of solder are 0.8mm, 1mm, 1.2mm etc, and we produce the tin solder ranging fro 0.3mm up to 3.2mm thick. The purpose of wide choices of diameter, is to make the tin solder provide the right amount solder to perfectly to fill into the solder joint. The 0.3mm tiny diameter of lead free wire solder is ideal for electronics applications that require precision and accuracy. The small diameter allows for more control and precision when soldering small components, such as surface mount devices (SMDs) and printed circuit boards (PCBs). It also reduces the risk of damaging nearby components during the soldering process.

Alloy Types of Lead Free Wire Solder:

Rosin core lead free wire solder is made of a mixture of tin, copper, and silver. The exact composition of the alloy may vary depending on the manufacturer and the intended use. However, the most common alloys used in electronics applications are:

SAC305 solder, which contains 96.5% tin, 3% silver, and 0.5% copper. This alloy has a low melting point, excellent wetting properties, and good mechanical strength.

SAC0307 solder, which contains 99% tin, 0.3% silver, and 0.7% copper. It's middle temperature, and has a most affordable price comparing to SAC305 but still keeps a quite nice soldering performance.

SAC07 solder, which contains 99.3% tin, 0.7% copper. It's the most afforable option of lead free wire solder, and suitable for most general soldering applications.

Benefits of 0.3mm Flux Rosin Core Lead Free Wire Tin Solder for Electronics

Using 0.3mm flux rosin core lead-free wire solder offers several benefits, including:

1. Safer for the environment and human health: Unlike traditional lead-based solders, rosin core lead-free wire solder is safer for the environment and human health.

2. Better conductivity: The alloy used in rosin core lead-free wire solder has excellent electrical conductivity, which ensures reliable and efficient performance of electronic devices.

3. Easy to use: The rosin flux core in the solder makes it easy to clean and remove oxides from the metal surfaces being soldered, allowing the solder to flow and bond the metals together.

4. Suitable for high precision applications and small components. Such small diameter will give a controllable small amount of solder to the joints and avoid excess amount of solder which could cause bridging.

Uses of 0.3mm Flux Rosin Core Lead Free Wire Tin Solder for Electronics:

Rosin core lead-free wire solder is widely used in various electronic applications, including:

1. Surface mount technology (SMT) and printed circuit board (PCB) assembly: The small diameter of the solder makes it ideal for soldering small components, such as SMDs and PCBs.

2. Electrical and electronic repairs: Rosin core lead-free wire solder is also used for repairing electronic devices, such as mobile phones, laptops, and televisions.

3. Automotive and aerospace industries: The excellent mechanical strength of the solder makes it suitable for use in the automotive and aerospace industries.

Advices of using 0.3mm Flux Rosin Core Lead Free Wire Tin Solder for Electronics

When using rosin core lead-free wire solder, it is essential to follow some best practices to ensure a successful soldering process. These include:

1. Clean the metal surfaces to be soldered thoroughly.

2. Use the correct temperature and soldering iron tip size.

3. Apply the solder to the joint, not the soldering iron.

4. Avoid overheating the components.

Conclusion

Rosin core lead-free wire solder is a popular type of solder used in various electronic applications. Its small diameter, rosin flux core, and alloy composition make it ideal for precision and accuracy. Using rosin core lead-free wire solder offers several benefits, including better conductivity, easy to use, and safer for the environment and human health. When using this type of solder, it is essential to follow best practices to ensure a successful soldering process.

If you need to buy 0.3mm flux rosin core lead free wire tin solder for electronics from China, please contact our sales team. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 0086 13450770997