China Tin Wire Solder Spool

China Tin Wire Solder Spool: A Comprehensive Guide

Tin wire solder spool is a popular product in the electronics industry, especially in China. It is a vital component in the manufacturing and repair of electronic devices. This article will provide a comprehensive guide on what tin solder spool is, the types of alloy, full specifications, feature of each alloy, and its application.

What is Tin Wire Solder Spool?

Tin solder spool is a type of wire that is made up of tin and other metals. It is used to join two metal parts together by melting the wire and letting it cool to form a bond. Tin solder spool is a crucial component in the electronics industry, as it is used to connect various components on printed circuit boards (PCBs). The tin wire is cast and winded onto a plastic spool and shown in a roll form.

Types of Alloys Tin Wire Solder Spool:

There are different types of alloy used in tin solder spool. The most common ones are lead-free and leaded solder wire. Each of these alloys has its unique features and applications.

Lead-Free Tin Wire Solder Spool

Lead-free alloy is a popular choice in the electronics industry due to its environmental friendliness. It is made up of tin, silver, and copper. The absence of lead in this alloy makes it safe for use in electronic devices that are meant for human consumption. Lead-free alloy is also easy to work with, as it has a low melting point. Silver alloy is a popular choice in the electronics industry due to its high conductivity. It is made up of tin, silver, and copper. This alloy is commonly used in the manufacturing of high-performance electronic devices such as computers and smartphones. The common alloys are Sn96.5Ag3Cu0.5 tin solder spool, Sn99Ag0.3Cu0.7 tin solder spool, Sn99.3Cu0.7 solder spool.

Leaded Tin Wire Solder Spool

Leaded alloy is another type of alloy used in tin solder spool. It is made up of tin and lead. This alloy is known for its strength and durability. Leaded alloy is commonly used in the manufacturing of high-temperature electronic devices such as power supplies and transformers. The common alloys are Sn63Pb37 solder spool, sn60pb40 solder spool, Sn40Pb60 solder spool.

Specifications of Tin Wire Solder Spool:

Tin solder spool comes in different specifications, including diameter, length, and weight. The diameter of the wire ranges from 0.5mm to 3mm, while the weight of the spool ranges from 100g to 1000g. And the tin wire is available in rosin flux core and solid core without flux.

Features of different Tin Wire Solder Spool:

Lead-Free Alloy Feature

Lead-free solder spool is environmentally friendly, as it does not contain lead. This alloy is commonly used in the manufacturing of electronic devices that are meant for human consumption. Silver alloy is known for its high conductivity, making it ideal for use in high-performance electronic devices such as computers and smartphones. It is also corrosion-resistant, making it suitable for use in harsh environments.

Leaded Alloy Feature

Leaded solder spool is known for its strength, durability and affordable price. It has a bit lower melting point than lead free solder, making it easier to use, and the solder joint is firm and strong. And cost wise it's much cheaper than lead free alloys.

Application of Different Alloys of Solder Spool:

Lead-Free Alloy Application

Lead-free alloy is commonly used in the manufacturing of electronic devices that are meant for human consumption, such as medical devices and food processing equipment.

Leaded Alloy Application

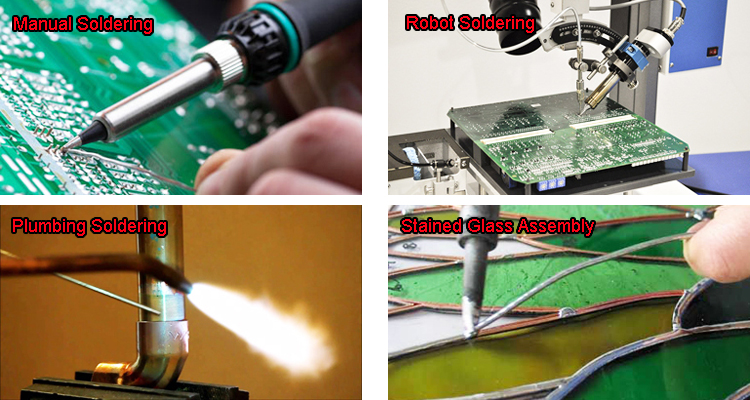

Leaded alloy is commonly used in the manufacturing of many general electronics soldering, metal joinery etc.

Conclusion

In conclusion, tin solder spool is a crucial component in the electronics industry. There are different types of alloy used in tin solder spool, including lead-free, leaded, and silver. Each of these alloys has its unique features and applications. When choosing a tin solder spool, it is essential to consider the alloy type, diameter, length, and weight.

If you need to buy tin wire solder spool from China, please contact our sales team, Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 0086 13450770997

Hits: 【Print】