Tin Leaded LED SMD Solder Paste 63/37 183C

Tin Leaded LED SMD Solder Paste 63/37 183C: A Comprehensive Guide

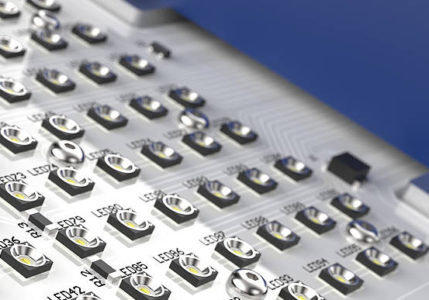

Soldering is a crucial process in the electronics industry. It involves joining two metal surfaces using a soldering material. One of the most commonly used soldering materials is solder paste. Solder paste is a mixture of tiny solder particles and flux. It is used in surface mount technology (SMT) to attach electronic components to printed circuit boards (PCBs). In this article, we will discuss tin leaded LED SMD solder paste 63/37 183C, its specifications, features, advantages, how to use it, tips, packing, and storage.

Specifications of Tin Leaded LED SMD Solder Paste 63/37 183C

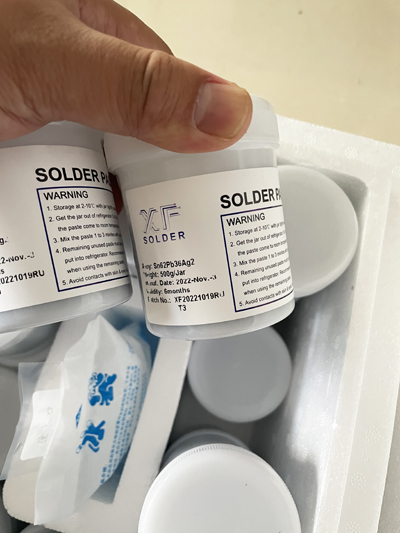

Solder paste 63/37 is a type of solder paste that contains 63% tin and 37% lead. The melting point of this solder paste is 183°C (known as solder paste 183 series). It is designed specifically for LED surface mount devices (SMDs). It has a fine particle size of 25-45 microns (T3 powder), which makes it suitable for small components. The viscosity of this tin leaded solder paste is good, easy to print on to LED.

Features and Advantages of Tin Leaded LED SMD Solder Paste 63/37 183C

LED SMD solder paste 63/37 has several features and advantages that make it an excellent choice for LED SMDs. Firstly, it has excellent wetting properties, which means it can easily spread and adhere to the surfaces it is applied to. This ensures a strong and reliable bond between the LED chip component and the PCB. Secondly, it has a low voiding rate, which means it minimizes the formation of air pockets or voids between the LED component and the PCB. This is important because air pockets can cause reliability issues and affect the performance of the device. Thirdly, it has a long stencil life, which means it can remain usable for a longer period. This reduces the need for frequent stencil cleaning and replacement, which can save time and money. Finally, the solder paste 183C has lpw melting point, that means it won't need a high working temperature and this will protect the LED SMD assembly from damage by heat.

How to Use Tin Leaded LED SMD Solder Paste 63/37 183C

Using tin leaded tin leaded solder paste 63/37 is a straightforward process. Firstly, the PCB should be cleaned and prepared. Secondly, the solder paste should be applied to the pads on the PCB using a stencil. The stencil should be aligned correctly to ensure accurate placement of the solder paste. Thirdly, the LED SMD chip components should be placed on the solder paste using a pick and place machine. The LED SMD components should be aligned correctly to ensure accurate placement. Fourthly, the PCB should be heated in a reflow oven to melt the led smd solder paste and form a strong bond between the component and the PCB.

Packing and Storage of Tin Leaded LED SMD Solder Paste 63/37 183C:

Solder paste 63/37 183C is usually packed in syringes or jars. The packaging should be airtight to prevent the solder paste from drying out or becoming contaminated. The solder paste should be stored in a cool and dry place, away from direct sunlight and sources of heat. It should be kept at a temperature between 0°C and 10°C to ensure its shelf life is maximized.

Conclusion

Tin leaded LED SMD solder paste 63/37 183C is an excellent choice for soldering LED SMDs. It has excellent wetting properties, a low voiding rate, and a long stencil life. It is easy to use and provides a strong and reliable bond between the component and the PCB. By following the tips outlined in this article, you can ensure the best results when using this solder paste. Remember to store it correctly to ensure its shelf life is maximized.

If you need to buy Tin Leaded LED SMD Solder Paste 63/37 183C from China, please contact us. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 0086 13450770997

Hits: 【Print】