SMD Solder Paste Lead 60/40

SMD Solder Paste Lead 60/40: The Ideal Solution for SMD Soldering

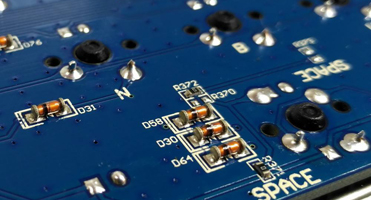

Surface mount device (SMD) soldering is a critical process in electronic manufacturing. It involves attaching electronic components to a printed circuit board (PCB) using solder paste. Solder paste is a mixture of tiny solder particles and flux, which is applied to the PCB before heating to melt the solder and form a bond between the component and the board. SMD soldering requires a specific type of solder paste, and SMD Solder Paste Lead 60/40 is the ideal solution.

What is SMD Solder Paste Lead 60/40?

Solder Paste 60/40 is a high-quality solder paste that is specifically designed for SMD soldering. This solder paste lead is a mixture of 60% tin and 40% lead, which makes it an ideal choice for SMD soldering. The lead content in the solder paste helps to improve the wetting and flow characteristics of the paste, making it easier to apply and ensuring a strong bond between the component and the board. And melting point of this SMD solder paste is low, just between 183 to 190℃, this will prevent the SMD components to be damanged by heat during the assembly process.

Why is SMD Solder Paste Lead 60/40 Good for SMD Soldering?

Solder Paste Lead 60/40 is the perfect choice for SMD soldering for several reasons. Firstly, the lead content in the paste helps to reduce the surface tension of the solder, which makes it easier to apply and ensures a strong bond between the component and the board. Secondly, the 60/40 ratio of tin and lead in the paste ensures a good balance between strength and flexibility, which is essential for SMD soldering. Finally, the SMD solder paste has excellent wetting and flow characteristics, which means that it can easily flow into the small gaps between the component and the board, ensuring a strong bond.

How to Use SMD Solder Paste Lead 60/40 for SMD Soldering

Using Solder Paste 60/40 for SMD soldering is a straightforward process. Firstly, the PCB should be cleaned thoroughly to remove any dirt or debris. The solder paste lead should then be applied to the pads on the PCB using a stencil or a syringe. The SMD component should then be placed on the paste, and the board should be heated using a reflow oven or a hot air gun. The heating process will melt the solder paste, forming a bond between the component and the board.

In conclusion, SMD Solder Paste Lead 60/40 is the ideal solution for SMD soldering. Its high-quality features make it an excellent choice for electronic manufacturing, ensuring a strong bond between the component and the board. By following the simple steps outlined above, you can easily use SMD Solder Paste Lead 60/40 for SMD soldering, making your electronic manufacturing process more efficient and effective.

If you need to buy SMD Solder Paste Lead 60/40 from China, please contact us. Email: xfsolder@gmail.com or xfsolder@163.com ; Whatsapp/Wechat: 0086 13450770997

Hits: 【Print】