| Name: | Lead Free Solder Bar |

| Product Type: | Lead Free Solder Bar |

| Place of Origin: | Foshan, China |

| Composition: | Sn99.3Cu0.7 |

| Percentage of other metal: | Ag, Cu as per client's request |

| Diemension: | 29.5cmx1.5cmx1.0cm |

| Weigth: | around 400g/PC, total 25kg/box (48PCS/box) |

| Application: | Lead-free automatic wave soldering, applicable to mix substrate or the general wave soldering |

Product Description

Lead Free Solder Bar:

Our company provides Lead Free Solder Bar (RoHS compliant) with a variety of alloy composition for customer choice.

We accept both big orders and small orders. Big order will be delivered by sea, small order will be delivered by courier service.

Whatsapp / Wechat: 008613450770997 ; Email: xfsolder@gmail.com or xfsolder@163.com , or fill in the Contact Form in the bottom of this page.

Basic Information of Lead Free Solder Bar:

| Alloy composition (wt.%) | Melting point℃ | Working point ℃ |

| Type | ||

| SAC305 Sn96.5Ag3.0Cu0.5 | 217-219 | 280-320 |

| SAC300 Sn97Ag3.0 | 217-220 | 280-320 |

| SAC0307 Sn99Ag0.3Cu0.7 | 217-225 | 280-320 |

| SAC07 Sn99.3Cu0.7 | 227 | 280-320 |

Color: Silvery

Size: approximate 29.5 * 1.5 * 1CM

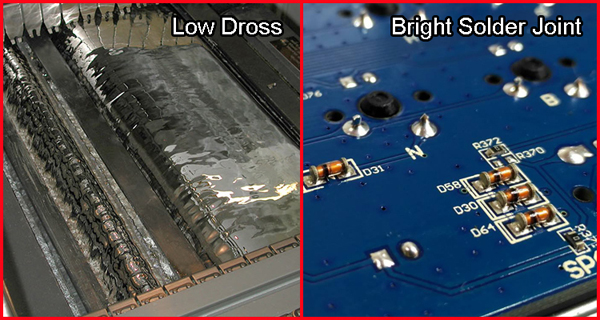

Features of Tin Lead Free Solder Bar:

1. Eutectic alloy.

2. Bridge-free and icicle-free

soldering.

3. Smooth, bright, well-formed fillets,

free of gross micro-cracks, irrespective of the cooling rate.

4. Good through-hole penetration.

5. Good topside fillet formation.

6. Dross rate equal or lower than

tin-lead solder.

7. Does not require a nitrogen

atmosphere.

8. Does not erode copper from holes,

pads and tracks.

9. Low rate of copper leaching makes it

easy to control the copper content of the solder bath.

10. Lower aggressiveness to stainless

steel and other solder pot materials as compared to tin-silver-copper alloys.

11. Thermal fatigue resistance and creep

strength better than tin-lead.

12. Slow, even growth of the

intermetallic layer at the solder/substrate interface.

13. Also performs well in selective and dip soldering.

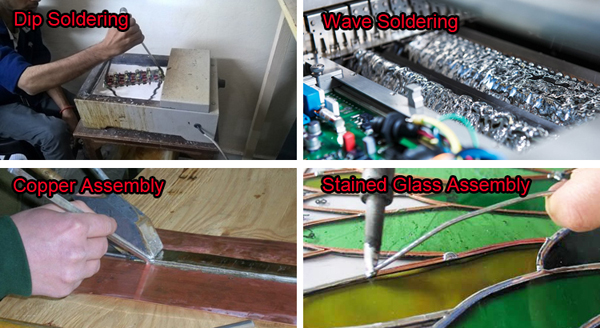

Applications of Lead Free Solder Bar

1. Dip soldering or Wave soldering of electronic components such as PCBA, THT

2. Soldering of metals, such as copper roofing joinery

3. Assembly of stained glass, silver jewelry etc

4. Other generally tinning purpose.

Packing:

Solder bar is packaged with cartonNeutral packing or OEM packing is available

Lead time:

We have a lot of stock of Tin Lead Free Solder Bar, if order quantity is not very big, we can send the goods right after receive payment. If order quantity is big, then delivery time is 10days after deposit received.Shipping term:

Small order of tin lead solder bar, will be sent by courier (DHL, FEDEX, TNT and so on). For bigger order quantity, we suggest to ship them by air or by sea. We are near Foshan, Rongqi Port / Guangzhou Port.

Production of Lead Free Solder Bar