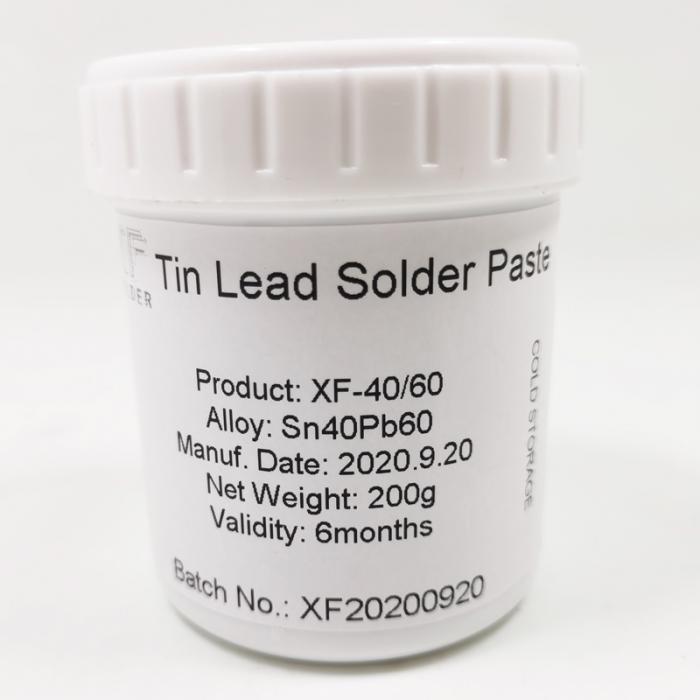

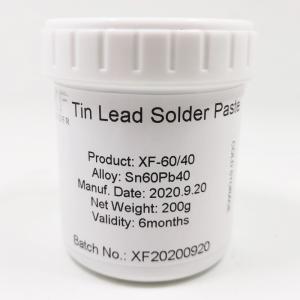

| Name: | Solder Paste 40/60 Sn40Pb60 |

| Name: | Tin Lead Solder Paste |

| Alloy: | Tin Lead |

| Composition: | Sn40Pb60 |

| Flux: | No clean flux |

| Applications: | Reflow soldering of electronics assembly |

| Country of Origin: | China |

Product Description

Tin Lead Solder Paste 40/60 Sn40Pb60

Tin Lead Solder Paste 40/60 Sn40Pb60 is a paste that is mixed with a no clean flux with tin lead alloy powder 40/60. It consisted of 40% tin and 60% lead.

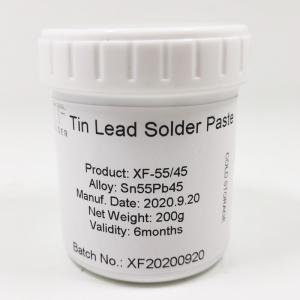

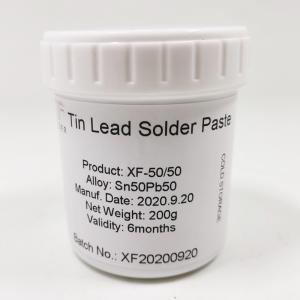

Basic information of Tin Lead Solder Paste 40/60 Sn40Pb60:

Composition: Sn40Pb60, it's a leaded tin alloy.

Powder size: Type 3, 25 to 45 microns. Other powder size available upon request.

Flux: No clean type (about 11.5%)

Melting Point: 183℃ to 238

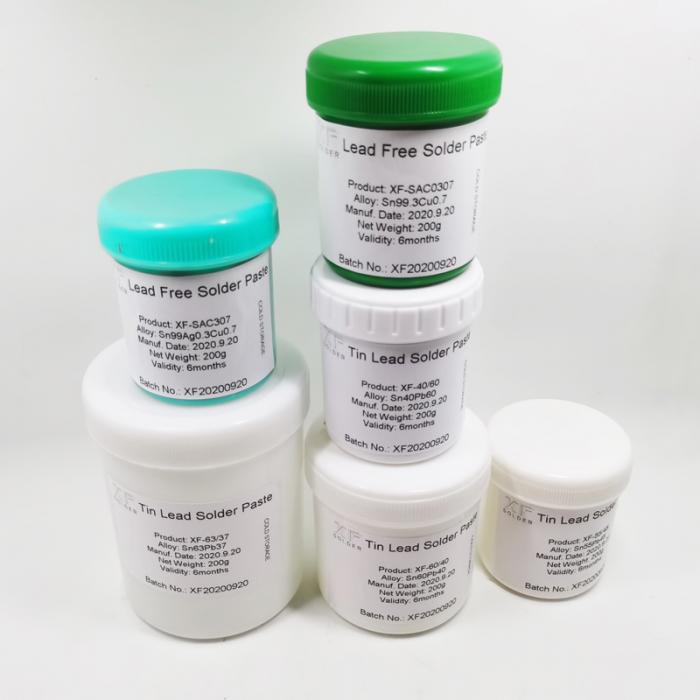

Packing: Jar or Syringe.

Weight: 200g/jar, 500g/jar, 1000g/jar, 2000g/jar or other weight as per customers’ requirements.

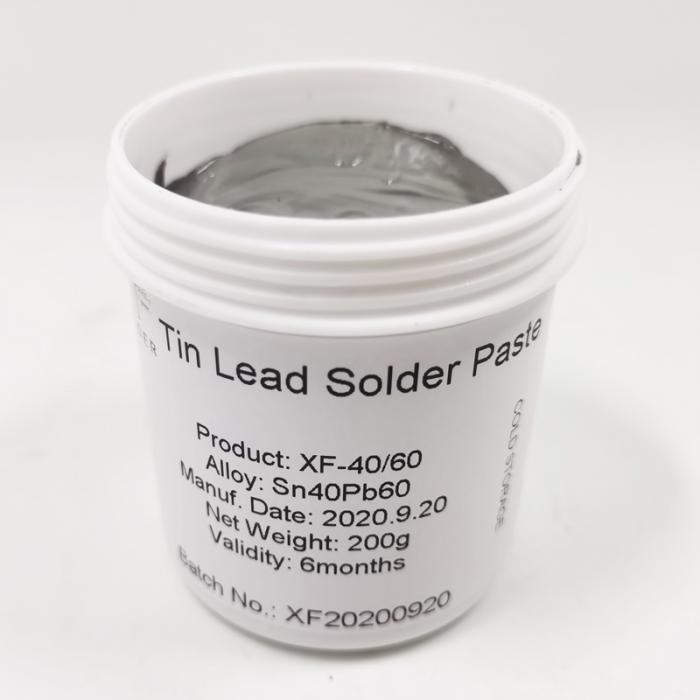

Color & Appearance of Paste: Metallic grey paste form.

Applications of Tin Lead Solder Paste 40/60 Sn40Pb60:

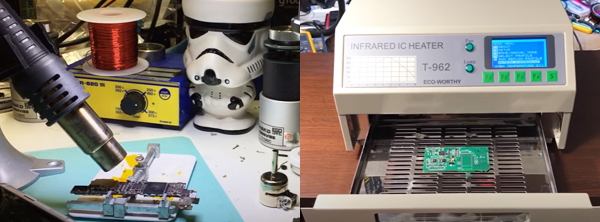

Solder paste 40/60 is mainly used for SMT (surface mount technology) of PCB assembly, BGA etc. Solder paste is suitable for assembly of small electronic parts or soldering projects by stencil printing. Tin lead solder paste Sn40Pb60 is generally soldered through reflow soldering method, used for LED lighting or other PCB soldering.

Feature of Tin Lead Solder Paste 40/60 Sn40Pb60:

1. Good wetting property. Solder paste 40/60 can melt and flow well to form a nice solder bead.

2. No clean flux. The residue of tin lead solder paste Sn40Pb60 after soldering is neutral, non corrosive and transparent, in most general applications there is no need to do cleaning.

3. Stable viscosity during the continuous printing process.

4. Bright & firm solder joints after soldering.

5. Cost wise it's quite affordable when comparing to solder paste 63/37 or lead free solder paste.

Using & Storage of Tin Lead Solder Paste 40/60 Sn40Pb60:

1. Recommended storage of tin lead solder paste 40/60: kept in refrigerator at temperature between 0 to 10℃.

2. Solder paste Sn40Pb60 must be taken out of the refrigerator at least 3 to 6 hours prior to use. This will give the paste enough time to come to thermal equilibrium with the environment.

3. We recommend using out the solder paste 40/60 after the jar is open each time. Mix the solder paste gently for at least one minute after fresh jar is open. In case there’s still leftover paste after using, it must be tightly sealed and refrigerated when not in use. Before re-using, it’s a must to double check if the solder pastes hasn’t become separated or thicken to its usual state.

4. Read and follow TDS of solder paste Sn40Pb60 before using.